Metal Ore Crushing & Processing

Metal Ore Crushing & Processing

Non-Metallic Ore Crushing & Processing

Non-Metallic Ore Crushing & Processing

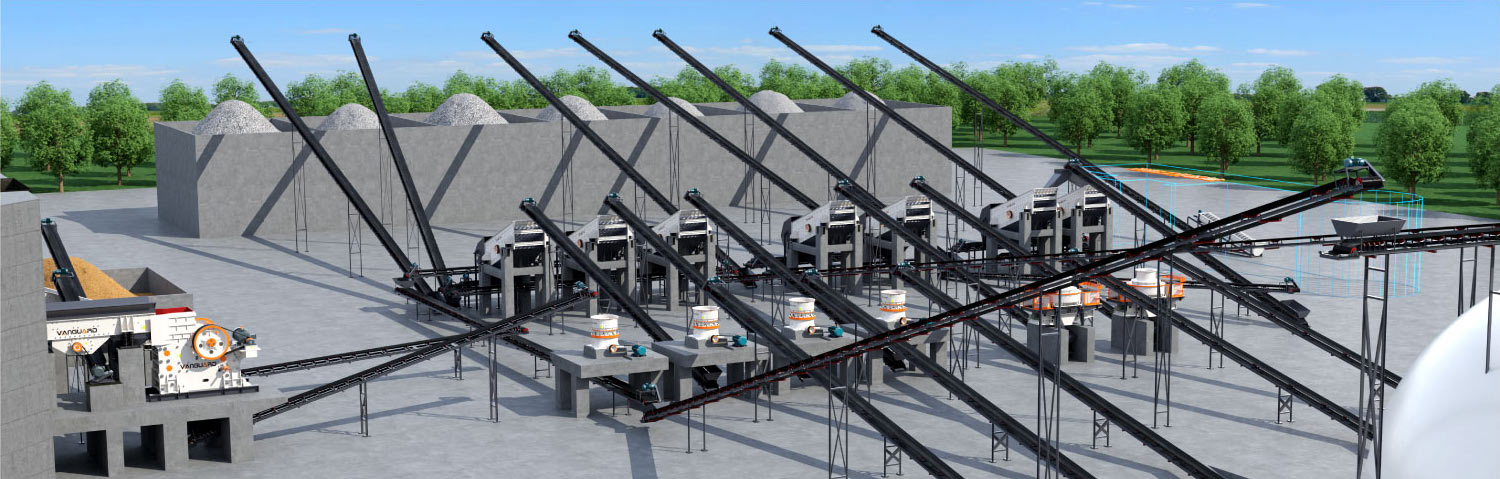

Stone Crushing Line Crushing & Processing

Stone Crushing Line Crushing & Processing

Construction Waste Crushing and Reuse

Construction Waste Crushing and Reuse

|

Model |

Feed size Opening(mm) |

Maximum feed size (mm) |

Adjustable size Discharge opening(mm) |

capacity (tons/hour) |

strength (kilowatt) |

|

PE150×250 |

150×250 |

125 |

10-40 |

1-3 |

5.5 |

|

PE150×750 |

150×750 |

125 |

18-48 |

8-25 |

15 |

|

PE250×400 |

250×400 |

210 |

20-60 |

5-20 |

15 |

|

PE400×600 |

400×600 |

340 |

40-100 |

16-65 |

30 |

|

PE500×750 |

500×750 |

425 |

50-100 |

45-100 |

55 |

|

PE600×900 |

600×900 |

500 |

65-160 |

60-160 |

75 |

|

PE750×1060 |

750×1060 |

630 |

80-160 |

110-320 |

110 |

|

PE800×1060 |

800×1060 |

640 |

130-190 |

130-330 |

110 |

|

PE900×1200 |

900×1200 |

750 |

95-210 |

220-450 |

132 |

|

PE1000×1200 |

1000×1200 |

850 |

110-235 |

280-560 |

160 |

|

PE1200×1500 |

1200×1500 |

1020 |

150-300 |

400-800 |

220 |

|

PE1500×1800 |

1500×1800 |

1200 |

210-360 |

520-1100 |

280 |

|

PEX250×750 |

250×750 |

210 |

25-60 |

13-35 |

22 |

|

PEX250×1000 |

250×1000 |

210 |

25-60 |

16-52 |

30 |

|

PEX250×1200 |

250×1200 |

210 |

25-60 |

20-65 |

37 |

|

PEX300×1300 |

300×1300 |

250 |

20-90 |

30-105 |

55 |

| Model | Cavity | Open side feeding size(mm) | Closed side feeding size(mm) | Discharge Port Size(mm) | Motor Power(kW) | Closed Edge Material-discharging Port(mm) Output(TPH) | |||||||||||

| 6mm | 8mm | 10mm | 13mm | 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 45mm | 51mm | ||||||

| CP200 | C Coarse | 235 | 190 | 19 | 160 | 60-75 | 70-90 | 85-115 | 115-145 | 135-175 | 145-185 | 155-195 | 165-215 | 185-230 | 205-245 | ||

| M Middle | 171 | 120 | 16 | ||||||||||||||

| F1 Fine | 150 | 95 | 13 | ||||||||||||||

| F2 Extra fine | 116 | 70 | 8 | ||||||||||||||

| CP300 | C1 Extra Coarse | 265 | 230 | 25 | 220 | 75-95 | 100-130 | 110-140 | 145-180 | 170-215 | 190-230 | 220-260 | 225-275 | 245-320 | 300-375 | 345-430 | |

| C2 Coarse | 240 | 210 | 20 | ||||||||||||||

| M Middle | 190 | 150 | 15 | ||||||||||||||

| F1 Fine | 145 | 105 | 11 | ||||||||||||||

| F2 Extra fine | 120 | 80 | 8 | ||||||||||||||

| CP400 | C1 Extra Coarse | 360 | 290 | 30 | 315 | 105-140 | 135-170 | 180-225 | 215-175 | 250-320 | 275-345 | 285-365 | 315-425 | 350-480 | 400-540 | 455-615 | |

| C2 Coarse | 310 | 250 | 25 | ||||||||||||||

| M Middle | 260 | 196 | 20 | ||||||||||||||

| F1 Fine | 182 | 110 | 13 | ||||||||||||||

| F2 Extra fine | 135 | 90 | 10 | ||||||||||||||

| CP500 | C1 Extra Coarse | 370 | 330 | 38 | 400 | 135-170 | 170-220 | 225-290 | 270-345 | 310-400 | 340-425 | 360-450 | 400-530 | 425-585 | 500-670 | 560-770 | |

| C2 Coarse | 320 | 290 | 28 | ||||||||||||||

| M Middle | 245 | 210 | 22 | ||||||||||||||

| F1 Fine | 180 | 130 | 13 | ||||||||||||||

| F2 Extra fine | 150 | 95 | 10 | ||||||||||||||

| CP800 | C1 Extra Coarse | 450 | 352 | 38 | 630 | 240-335 | 315-420 | 375-500 | 420-540 | 465-590 | 490-725 | 545-790 | 585-920 | 670-990 | 765-1100 | ||

| C2 Coarse | 373 | 298 | 32 | ||||||||||||||

| M Middle | 340 | 275 | 25 | ||||||||||||||

| F1 Fine | 280 | 230 | 16 | ||||||||||||||

| F2 Extra fine | 235 | 150 | 10 | ||||||||||||||

The above capacity is based on 1.6T/m³ material density under open circular crushing plant.The capacity is related to physical properties of the crushing material, feeding size and its composition, and the actual capacity may be different due to different conditions.

|

Model |

Max. Feeding Size (mm) |

Product Particle Size(mm) |

Capacity (t/h) |

Power(kW) |

|

6FX1010 |

400×400×500 |

20-100 |

70-150 |

90-132 |

|

6FX1210 |

400×400×600 |

20-100 |

100-285 |

110-160 |

|

6FX1214 |

400×400×600 |

20-100 |

150-400 |

160-200 |

|

6FX1315 |

400×400×700 |

20-100 |

180-500 |

200-250 |

|

6FX1317 |

400×400×700 |

20-100 |

200-600 |

200-315 |

|

6FX1415 |

600×600×900 |

100-200 |

400-700 |

315-400 |

|

6FX1620 |

600×600×1000 |

100-200 |

600-900 |

400-500 |

| Model | Layer of Screen | Size of Sieve Pore (mm) | Max. Feeding Size (mm) | Capacity (m³/h) | Double Amplitude (mm) | Model of Motor | Motor Power (kW) | Screen Specaification (mm) |

| 2YA1548 | 2 | 3~100 | 300 | 22~160 | 8 | Y160L-4 | 15 | 1500×4800 |

| 3YA1548 | 3 | 3~100 | 300 | 22~160 | 8 | Y160L-4 | 15 | 1500×4800 |

| 4YA1548 | 4 | 3~100 | 300 | 22~160 | 8 | Y160L-4 | 15 | 1500×4800 |

| 2YA1848 | 2 | 3~100 | 300 | 32~276 | 8 | Y180M-4 | 18.5 | 1800×4800 |

| 3YA1848 | 3 | 3~100 | 300 | 32~276 | 8 | Y180M-4 | 18.5 | 1800×4800 |

| 4YA1848 | 4 | 3~100 | 300 | 32~276 | 8 | Y180M-4 | 18.5 | 1800×4800 |

| 2YA1860 | 2 | 3~100 | 300 | 65~586 | 8 | Y180M-4 | 22 | 1800×6000 |

| 3YA1860 | 3 | 3~100 | 300 | 65~586 | 8 | Y180M-4 | 22 | 1800×6000 |

| 4YA1860 | 4 | 3~100 | 300 | 65~586 | 8 | Y180M-4 | 22 | 1800×6000 |

| 2YA2160 | 2 | 3~100 | 300 | 81~720 | 8 | Y200L-4 | 30 | 2100×6000 |

| 3YA2160 | 3 | 3~100 | 300 | 81~720 | 8 | Y200L-4 | 30 | 2100×6000 |

| 4YA2160 | 4 | 3~100 | 300 | 81~720 | 8 | Y200L-4 | 37 | 2100×6000 |

| 2YA2460 | 2 | 3~150 | 300 | 90~810 | 8 | Y225S-4 | 37 | 2400×6000 |

| 3YA2460 | 3 | 3~150 | 300 | 90~810 | 8 | Y225S-4 | 37 | 2400×6000 |

| 4YA2460 | 4 | 3~150 | 300 | 90~810 | 8 | Y225S-4 | 37 | 2400×6000 |

| 2YK3072 | 2 | 3~200 | 300 | 180~1300 | 8 | Y200L-4 | 30×2 | 3000×7200 |

| 3YK3072 | 3 | 3~200 | 300 | 180~1300 | 8 | Y200L-4 | 30×2 | 3000×7200 |