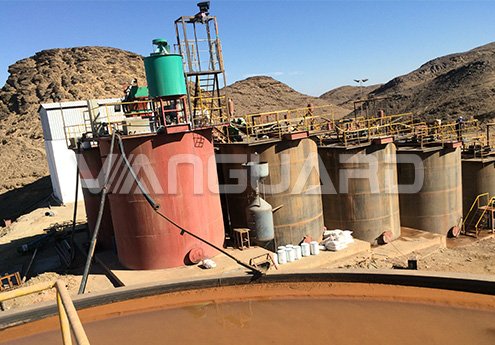

Product introduction:The thickener is a piece of important equipment to increase the concentration of the slurry and obtain the proper concentration in the production process. It is generally divided into central transmission and peripheral transmission, which is often used for the concentration of concentrates, middle ore and tailings in concentrators.

| Model | Transfer Method | Concentration Tank | Capacity(t/d) | Matching Motor | Weight(kg) | ||

| Diameter(m) | Central Depth(m) | Model | Power(kw) | ||||

| NZS-1 | Center Drive | 1.8 | 1.8 | 5.6 | Y90L-6 | 1.1 | 1300 |

| NZS-3 | Center Drive | 3.6 | 1.8 | 22.4 | Y90L-6 | 1.1 | 2975 |

| NZS-6 | Center Drive | 6 | 3 | 62 | Y100L2-4 | 3 | 8700 |

| NZS-9 | Center Drive | 9 | 3 | 140 | Y132S-6 | 3 | 16682 |

| NZS-12 | Center Drive | 12 | 3.5 | 250 | Y132S-6 | 3 | 33131 |

| NG-15 | Peripheral Roller | 15 | 3.5 | 390 | Y132M2-6 | 5.5 | 9120 |

| NG-18 | Peripheral Roller | 18 | 3.5 | 560 | Y132M2-6 | 5.5 | 10000 |

| NG-24 | Peripheral Roller | 24 | 3.7 | 1000 | Y160M-6 | 7.5 | 24000 |

| NG-30 | Peripheral Roller | 30 | 3.6 | 1570 | Y160M-6 | 7.5 | 26420 |

| NT-15 | Peripheral Rack | 15 | 3.5 | 390 | Y132M2-6 | 5.5 | 11000 |

| NT-18 | Peripheral Rack | 18 | 3.5 | 560 | Y132M2-6 | 5.5 | 12120 |

| NT-24 | Peripheral Rack | 24 | 3.7 | 1000 | Y160M-6 | 7.5 | 28270 |

| NT-30 | Peripheral Rack | 30 | 3.6 | 1570 | Y160M-6 | 7.5 | 30888 |

| NT-45 | Peripheral Rack | 45 | 5.1 | 2400 | Y160L-6 | 11 | 58640 |

| NT-50 | Peripheral Rack | 50 | 4.5 | 3000 | Y160L-6 | 11 | 65920 |

| NT-53 | Peripheral Rack | 53 | 5.1 | 3400 | Y160L-6 | 11 | 69410 |