Metal Ore Crushing & Processing

Metal Ore Crushing & Processing

Non-Metallic Ore Crushing & Processing

Non-Metallic Ore Crushing & Processing

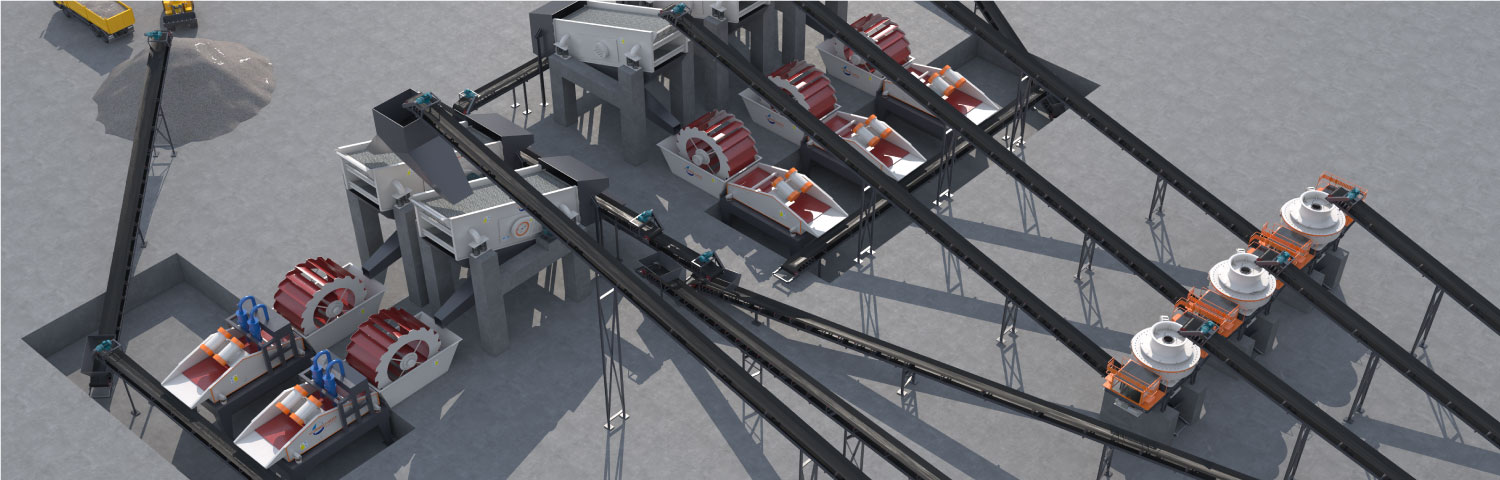

Stone Crushing Line Crushing & Processing

Stone Crushing Line Crushing & Processing

Construction Waste Crushing and Reuse

Construction Waste Crushing and Reuse

|

Model |

5X7615 |

5X8522 |

5X9532 |

5X1145 |

|||

|

Capacity (t/h) |

Central Feeding |

150~280 |

240~380 |

350~540 |

500~640 |

||

|

Fully Central Feeding |

|||||||

|

70~140 |

120~200 |

180~280 |

250~360 |

||||

|

Max. Feeding Size (mm)

|

Soft Material |

<35 |

<40 |

<45 |

<50 |

||

|

Hard Material |

<30 |

<35 |

<40 |

<45 |

|||

|

Rotation Speed (r/min) |

1700~1900 |

1500~1700 |

1300~1510 |

1100~1310 |

|||

|

Double Motor Power (kW) |

150 |

220 |

320 |

440 |

|||

|

Overall Dimension LxWxH (mm) |

4100×2300×2300 |

4140×2500×2700 |

4560×2600×2900 |

5100×2790×3320 |

|||

|

Power Supply |

380V,50Hz |

||||||

|

Double Oil Oumps Motor’s Power (kW) |

2x0.31 |

||||||

|

Thin Oil Lubrication Station |

Safty Assurance |

Dual oil pump system stabilize oil supply; switch-off automatically without oil flow or oil pressure; |

|||||

|

Air cooling system /water cooling system available; preheating-start engine adopted. |

|||||||

| Power of Oil Tank Heater(kW) |

2 |

||||||

| Model | VSI7611 | VSI8518 | VSI9526 | VSI1140 | |

| Capacity(t/h) | Cascade and Central Feeding | 120~180 | 200~260 | 300~380 | 450~520 |

| Fully Central Feeding | 60~90 | 100~130 | 150~190 | 220~260 | |

|

Max. Feeding Size(mm) |

Soft Material | <35 | <40 | <45 | <50 |

| Hard Material | <30 | <35 | <40 | <45 | |

| Rotation Speed(r/min) | 1700~1890 | 1520~1690 | 1360~1510 | 1180~1310 | |

| Double Motor Power(kW) | 110 | 180 | 264 | 400 | |

| Overall Dimension L×W×H(mm) | 3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5000×2700×3300 | |

| Weight (t) | 11.8 | 14.5 | 17.8 | 25.6 | |

|

Thin Oil Lubrication Station |

Double Oil Pumps Motor's Power (kW) | 2×0.25 | |||

| Safty Assurance |

Dual oil pump system stabilize oil supply; switch-off automatically without oil flow or oil pressure; air cooling system /water cooling system available; preheating-start engine adopted. |

||||

| Overall Dimension L×W×H(mm) | 820×520×1270 | ||||

| Power of Oil Tank Heater(kW) | 2 | ||||

| Model | Separator specification | Size of dewatering screen | Dehydration Screen Power(KW) | Type of pump | Pump power(KW) | processing capacity(T) | Shape size | Remarks |

| WS8018 | 250 | 800*1800 | 0.75*2 | 2/3 | 11 | 5--10 | 2200*1400*2150 | ①The pump can be selected according to the amount of water on site. ②2/3 pump flow rate 45 tons / hour ③3/4 pump flow 80-100 tons / hour ④4/6 pump flow 300-360 tons / hour ⑤The pump can be selected according to the amount of water on site. |

| WS9020 | 300 | 900*2000 | 1.1*2 | 3/4 | 15 | 10--20 | 2500*1400*2300 | |

| WS1225 | 350 | 1200*2500 | 2.2*2 | 3/4 | 15 | 20--30 | 3000*1700*2300 | |

| WS1530 | 350*2 | 1500*3000 | 3.0*2 | 3/4 | 15*2 | 50--80 | 3100*2000*2500 | |

| 2WS1530 | 350*2 | 1500*3000 | 3.7*2 | 3/4 | 15*2 | 50--100 | 3100*2000*2800 | |

| WS1840 | 350*2 | 1800*4000 | 3.7*2 | 3/4 | 15*2 | 100--130 | 4200*2300*2800 | |

| 2WS1840 | 350*2 | 1800*4000 | 3*4 | 3/4 | 15*2 | 100--150 | 4550*2300*2800 | |

| WS2050 | 500*2 | 2000*5000 | 3.7*4 | 3/4或4/6 | 18.5*2 | 150--200 | 5200*2500*3100 | |

| 2WS2060 | 500*2 | 2000*6000 | 3.7*4 | 2/3 | 22*2 | 200--260 | 6500*2500*3100 |

|

Model |

XSD2610 |

XSD2816 |

XSD3016 |

XSD3620 |

|

Impeller of Diameter(mm) |

2600 |

2800 |

3000 |

3600 |

|

Feeding Size(mm) |

≤10 |

≤10 |

≤10 |

≤10 |

|

Capacity(t/h) |

20~60 |

30~60 |

70~120 |

80~160 |

|

Model of Motor |

Y160L-8 |

Y180L-8 |

Y200L-8 |

Y225S-8 |

|

Power(kW) |

7.5 |

11 |

15 |

18.5 |

|

Water Requirement(t/h) |

10-30 |

10-40 |

10-60 |

20-110 |

|

Weight(t) |

2.7 |

5.5 |

6.1 |

9.7 |

|

Dimension(L×W×H)(mm) |

3254×2060×2622 |

3810×2820×2883 |

3810×2820×3083 |

4624×3443×3680 |