Note: Specific production capacity is based on customer site configuration and production capacity.

Quarry, stone crushing processing, concrete mixing plant, etc.

Output size05, 12, 13 and various specifications

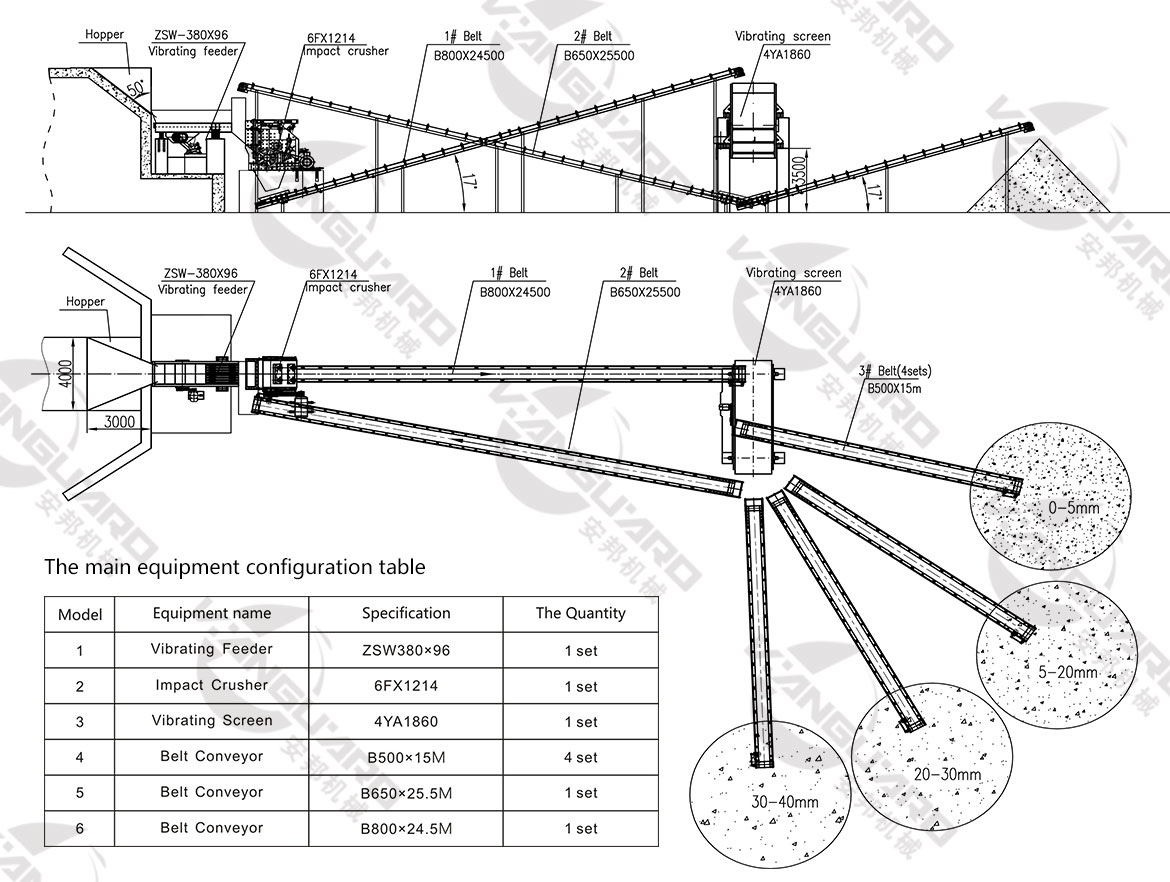

Purchase equipmentVibrating feeder, jaw crusher, impact crusher, circular vibrating screen, belt conveyor, centralized electronic control box, etc.

Stone production line is also called sand and gravel production line. It mainly consists of vibrating feeder, jaw crusher, impact crusher or cone crusher, circular vibrating screen, belt conveyor, centralized electronic control box and other equipment. The designed capacity is generally 50-800 T/H, or equipped with other equipment and tailor-made according to different processing needs of customers. Vanguard Machinery provides practical solutions for stone production line, including system layout, optimized configuration, high-quality equipment, equipment installation, technical support, after-sales service and other solutions.

1. Stone crushing production line has high automation, large crushing ratio, high production efficiency and large capacity. The crushed products are cubic with low needle-like content, no internal cracks and high pressure strength.

2. The equipment is simple maintenance and can bring considerable economic benefits to customers. The wearing parts are made of high-strength wear-resistant materials at home, which have low wear and tear with long service life.

3. The stone crushing production line has been successfully applied to the crushing of limestone, basalt, granite, cobblestone and other rocks. The quality of finished products fully meets the GB14685-2001 standard, which provides qualified aggregate for the industries of expressway, railway, water conservancy, concrete mixing plant and so on.