The large-scale power cuts occurred in many regions of my country, which caused factories to stop working or restrict production since September 2021. A comprehensive combination of factors, the main reasons is the long-term high coal price among them. Since this year, the national coal price has been rising, and 70% of my country's power generation is through coal. Due to the excessive increase in coal prices, power plants have less coal. The tight power supply because of the peak periods of power consumption in the Autumn and winter.

Coal is always a pillar industry in my country's economy, as well as an important basic energy source. It plays a pivotal role in a variety of industries after the crusher processing. Coal is hard in texture and solid in structure. Coking coal and vitreous coal are the common coals, and coking coal contains 18-26% more volatility. There are many coal crushing methods, such as crushing, impact, and extrusion. But in its actual use, the equipment combines two or more forms for crushing and generally not in a certain form. Common ones are jaw crusher, hammer crusher, impact crusher, etc. After the coal crushed which has a wide range of uses and high profits.

1. Used for coking, crushing coke coal into 50mm or less. As an important raw material for ironmaking, coke is a good fuel with high heat and no emit smoke.

2. Crushing the vitrinite coal into less than 20mm, used to produce coal gasification and to generate syngas, burned with a gas turbine to generate electricity, and can be converted into gasoline and diesel at the same time.

3. It is fast ignition during combustion and long flames, when the crushed coal in pellets, small lumps, and powders below 10mm, with a volatility of more than 30%, which is usually used in small chemical, power generation, and iron plants.

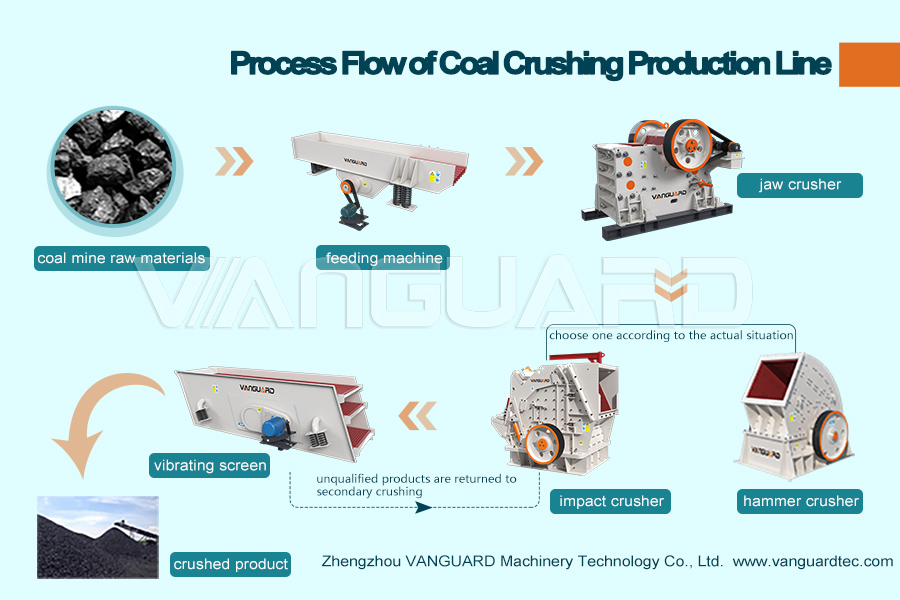

Vanguard Machinery coal crushing production line standard process flow

The large pieces of coal are evenly sent to the jaw crusher by the vibrating feeder through the silo for coarse crushing and then sent to the impact crushing or hammer crushing by the belt conveyor for secondary crushing. The finely crushed coal is sent to the vibrating screen by a conveyor for screening. According to different requirements, different particle sizes can be screened out, and the coal that meets the particle size requirements is sent to the finished product pile by the finished product belt conveyor; The coal that does not meet the particle size requirements is returned by the conveyor to impact crusher or hammer crusher and crushed it again, forming a closed circuit for multiple cycles until it meets the requirements. The particle size of the finished product can be combined and classified according to the needs of users, and dust removal equipment can be equipped to meet environmental protection requirements.

Vanguard Machinery coal crusher equipment has a variety of options

1. Jaw crusher (large reduction ratio, higher capacity)

Specifications of crushed coal products:feed size 0-1280mm, finished product 10-360mm

Motor power:75KW-250KW

Advantages of crushed coal:The crusher adopts a "V-shaped" crushing cavity design. The crushing cavity structure and moving jaw movement trajectory parameters are optimized, and the large stroke maximizes the feed size, capacity and reduction ratio.

2. Hammer crusher (Large feed size, one-time molding)

Specifications of crushed coal products:feed size ≤300mm, 0-5mm, 5-10mm, 10-20mm, 20-30mm

Motor power:75KW-250KW

Advantages of crushing coal:Hammer crusher crushes coal realizes one-times forming,under the premise of non-clogging. When crushed, coal will generally agglomerate. The multiple hammer cycles of hammer crusher can crush, not only crushed coal but also play a role in shaping with remarkable effect.

3. Impact crusher (crushing coal has a shaping effect)

Specifications of crushed coal products:feed size ≤800mm, finished products up to 0-30mm

Motor power:4P37-45KW, 6P250KW

Advantages of crushing coal:The impact crusher for crushing coal adopts the percussion principle with good discharge particle type. It is especially suitable for materials with low hardness such as coal gangue. In addition, it is low failure rate in the later periodvery, because of the resistant hammer head and a large moment of inertia mill and rotor.

4. Mobile crushing plant (high productivity, uniform finished product size)

Specifications of crushed coal products:feed size ≤800mm

Motor power:70KW-1000KW

Advantages of crushing coal:The mobile crushing plant is a high-efficiency advanced technology and complete functions crushing equipment that adopts a self-driving method. Under any terrain conditions, this equipment can reach any position of the worksite. This can reduce the handling of materials and facilitate the coordination of all auxiliary machinery and equipment. Its optimized design can meet the technical characteristics most needed by the crusher, with high productivity and uniform particle size of the finished product.