Note: Specific production capacity is based on customer site configuration and production capacity.

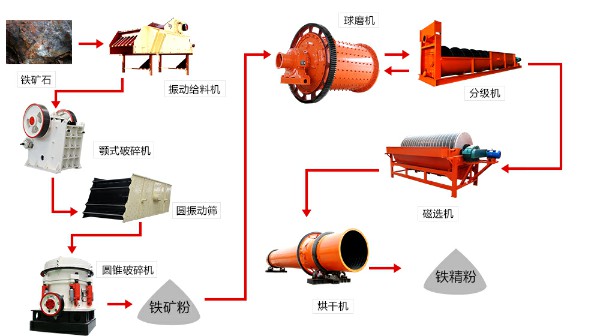

Magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size less than 3mm

Output sizenothing

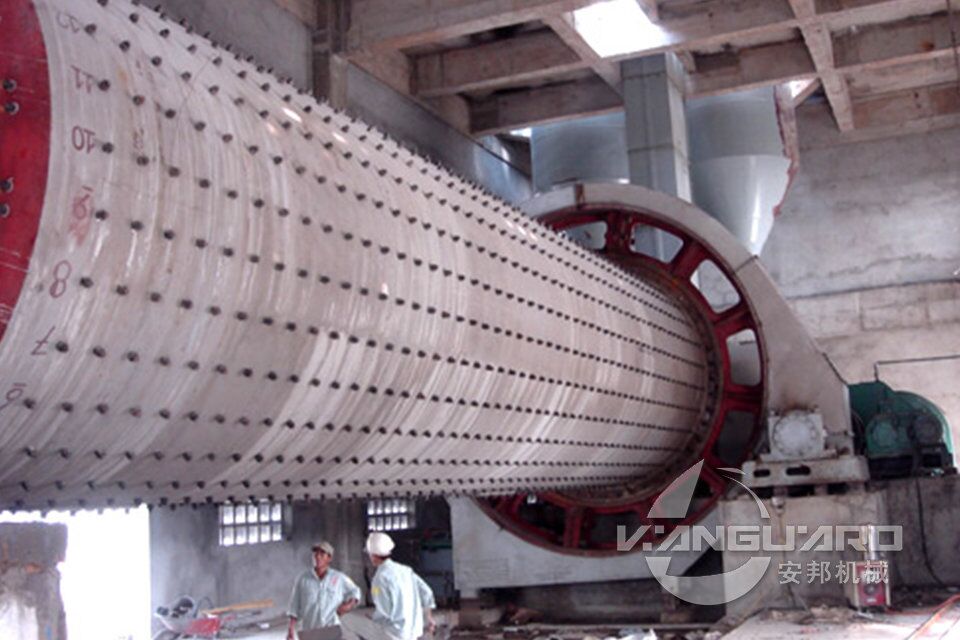

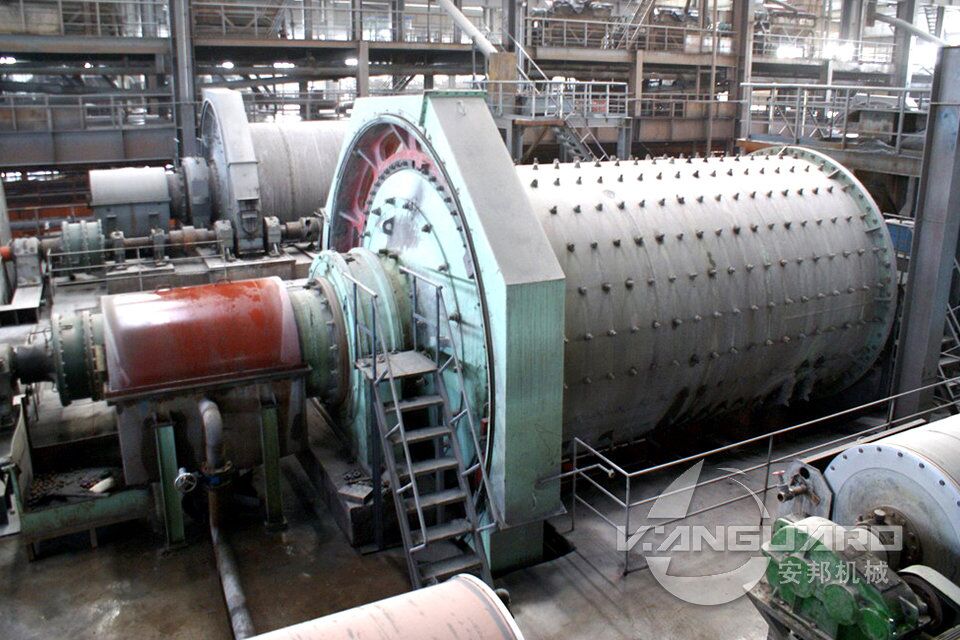

Purchase equipmentVibration feeder, jaw crusher, vibration screen, electromagnetic vibration feeder, ball mill, screw classifier, high frequency screen, magnetic separator, concentrator, etc.

The magnetic separation process of the new beneficiation production line consists of jaw crusher, ball mill, classifier, magnetic separator, thickener and dryer, etc. and work in with feeder, hoist and belt conveyor formed a complete production line. The production line has the advantages of high efficiency, low energy consumption, high capacity, reasonable and economical, which designs matching equipment according to the actual situation of customers.

1. Dust in magnetic separation is collected by dust removal device, which will not cause air pollution. It is a creative process with high efficiency, good quality and no environmental pollution.

2. The fundamentals of cost saving are reasonable design and selection of high-quality equipment. The magnetic separation production line allocated by our company, which is composed of advanced and high-quality equipment with efficient and energy-saving, simple operation, low failure rate and investment and high recovery rate.

3. Production line configuration adopt different separation processes according to different ore properties. And it can also optimize the design according to the different annual output and requirements of customers, so that the performance of magnetic separation production line can fully exploited.

4. The magnetic separation production line is equipped with advanced equipment, compact technology, small area, less capital investment and high income.