Granite is a hard igneous rock, mainly composed of quartz, feldspar, mica and other minerals. Its Moh's hardness is 5-7 with high strength, corrosion resistance, wear resistance and other properties. After sand making treatment, granite can be made into sand with excellent grain shape and uniform particle size. This kind of sand is an important construction material that can meet the demand for high-quality aggregates in engineering construction and also provides a reliable material basis for various engineering projects. In this article, we will discuss sand production rates, influencing factors, and typical production line configurations for granite sand production.

1. Sand production rate and influencing factors of granite sand making

The sand production rate of granite sand making is mainly affected by factors such as rock properties, rock size, crushing methods, and sand making equipment. According to relevant literature reports, the sand production rate of granite sand making is generally between 30% and 50%, that is, each ton of granite can produce 0.3-0.5 tons of sand. However, actual sand production rates may vary due to various factors.

Among them, the properties of rocks such as hardness and toughness have a great influence on the sand production rate, while the crushing method and sand making equipment can increase the sand production rate by selecting appropriate models and parameters.

(1) . Hardness and toughness

Generally speaking, the higher the hardness of granite, the more difficult it is to crush with the relatively low sand production rate. The harder and less tough granite is easier to crush with the relatively high sand production rate.

(2) . Rock size

The size of the rock is an important factor affecting the sand production rate. Generally, the larger the particle size of granite, the more difficult it is to crush. It requires greater crushing force and grinding force to crush it into sand and with a relatively low sand production rate. If with too large granite particles, it will increase equipment wear and energy consumption and reduce production efficiency. Therefore, in the process of making granite sand, granite of appropriate size needs to be selected as raw material according to the actual situation.

(3) . Other mineral content

The content of other minerals in granite will also affect the sand making effect. For example, if it contains higher amounts of mica, feldspar, quartz and other minerals, it may reduce the sand production rate.

2. Granite sand making production line configuration

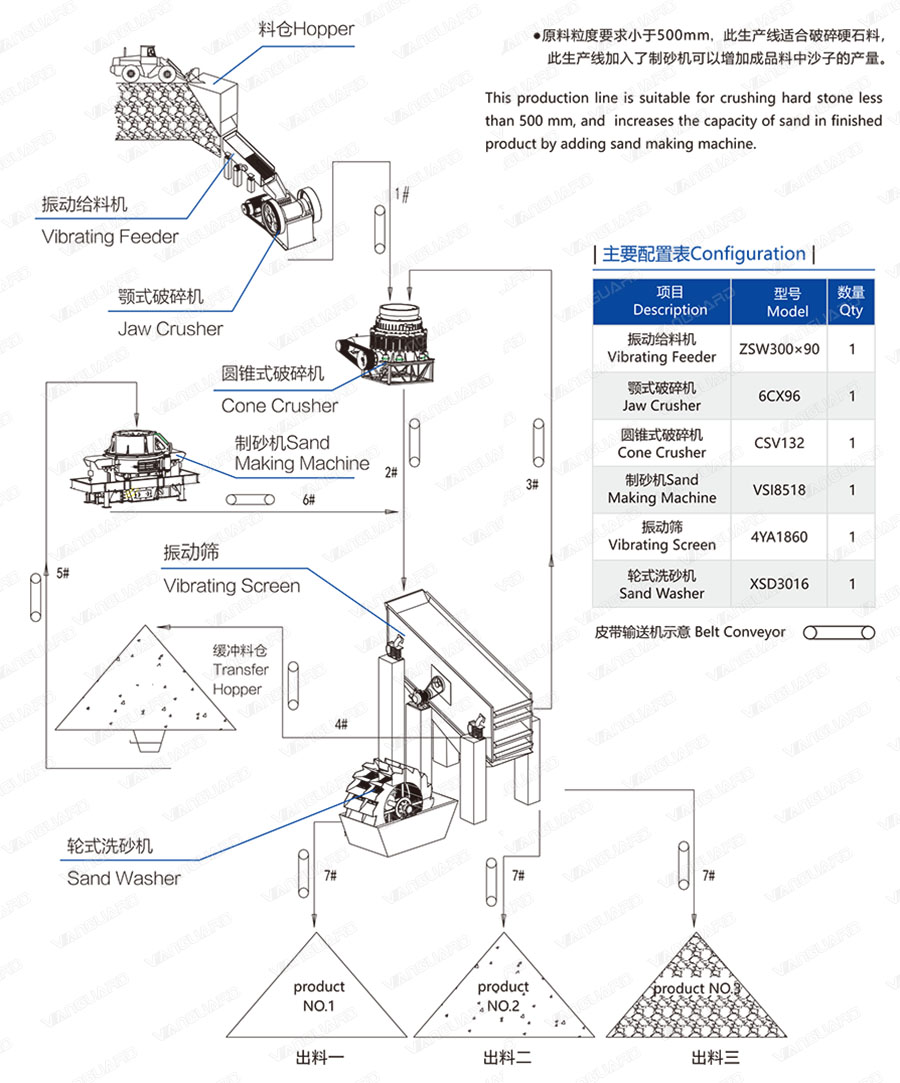

The granite sand making production line configuration usually includes a feeder, vibrating screen, jaw crusher, cone crusher, sand making machine, sand washing machine and other equipment. When configuring the granite sand making production line, it needs to be based on the capacity requirements, raw material characteristics, product requirements and other circumstances to select the appropriate equipment model. For example: for projects with small capacity and small material particle size, you can choose a fine jaw crusher to replace the cone crusher for secondary and tertiary crushing for medium and fine crushing; For projects with large capacity, then a cone crusher is needed to meet the capacity of thousands of tons/hour. Of course, budget is also an important factor to consider when configuring a granite sand making production line. If the budget is insufficient, other configurations can be selected to meet production needs.

Live video:

In the granite sand making production line, it also needs to be reasonably laid out. More crushing and less grinding links can be set up according to the actual situation. Production efficiency can be improved by adding equipment such as crushing equipment and fine sand recycling devices to achieve efficient and stable production. The specific configuration needs to be adjusted according to the actual situation. For example, if you need to produce finer sand, you may need to add sand making and sand washing links; If you need to increase the sand production rate, you may need to add crushing and sand making links. In addition, depending on the production scale and operation mode, fixed or mobile sand making machines can be selected to meet different production needs.

To sum up, when designing a granite sand making production line, you need to pay attention to several key points, including understanding the characteristics of granite, determining capacity, optimizing the process, selecting appropriate equipment, considering environmental protection factors, ensuring production safety, and considering investment costs and returns, etc. Reasonable equipment selection and parameter settings can increase the sand production rate, reduce production costs, improve production efficiency, and achieve the goal of sustainable development. Therefore, when designing and constructing a granite sand making production line, various factors should be fully considered and appropriate equipment models and parameters should be selected to achieve good production results.