As natural sand decreases and the national environmental protection policies increasingly become stringent , the demand for sand and gravel materials is strong, and the machine-made sand is in short supply. The configuration of an economical, environmentally friendly and efficient mechine-sand production line is essential for quarry owners. In general, the main structure of the gravel and sand production line includes: feeding equipment, crushing equipment, screening equipment, and washing equipment. Here are some tips and principles for a high-quality gravel and sand production line design and equipment selecting.

.

.

I.Overall Solution Design

The solution design of the whole production line mainly includes process flow design, layout design and equipment selecting design.

1. After defining customer's material, crushing demand and finished product granularity, we can fully discuss and select the most suitable process plan according to customer's investment cost and initial requirements.

2. According to the design of the main equipment determined by the process flow, the following aspects should be considered when laying out the production site according to the user's terrain:

(1)Distance between raw material and the feeding inlet of production line, the feeding site and drop height, equipment layout site, stacking yard and material output mode;

(2) Under the condition of smooth material flow, the belt conveyor should be set up as little and short as possible.

(3) Meet the design of intermediate stockyard and finished stockyard during operation and product transportation, and make full use of the site;

3. There are three main types of crushing and screening equipment: fixed, semi-mobile and mobile. Mobile crushing plant can be divided into wheel type and crawler type according to its moving mode. These three types can be used independently or in combination.

1. After defining customer's material, crushing demand and finished product granularity, we can fully discuss and select the most suitable process plan according to customer's investment cost and initial requirements.

2. According to the design of the main equipment determined by the process flow, the following aspects should be considered when laying out the production site according to the user's terrain:

(1)Distance between raw material and the feeding inlet of production line, the feeding site and drop height, equipment layout site, stacking yard and material output mode;

(2) Under the condition of smooth material flow, the belt conveyor should be set up as little and short as possible.

(3) Meet the design of intermediate stockyard and finished stockyard during operation and product transportation, and make full use of the site;

3. There are three main types of crushing and screening equipment: fixed, semi-mobile and mobile. Mobile crushing plant can be divided into wheel type and crawler type according to its moving mode. These three types can be used independently or in combination.

II.Model Selection Strategy: Performance and Advantages of Main Equipment

Different kinds of sand and stone pruduction site have different requirements in rock types, processing capacity and sand and stone products. Therefore, the crushing and screening equipment used in the design is also different.

1. Coarse Crushing Equipment

Vanguard Machinery coarse crushing products mainly include jaw crusher, impact crusher, etc.

1. Coarse Crushing Equipment

Vanguard Machinery coarse crushing products mainly include jaw crusher, impact crusher, etc.

Jaw crusher is mainly aimed at the crushing of bulk materials. The particle size of raw materials is less than 200 mm. Hard and soft stones can be crushed at the same time.

Advantages: It has the characteristics of large crushing ratio and uniform product size.

Advantages: It has the characteristics of large crushing ratio and uniform product size.

Impact crusher is mainly aimed at the crushing of rocks with moderate or low hardness and abrasion, and the grain size of raw materials should be less than 300 mm.

Advantages: Strong adaptability, excellent performance in coarse and medium crushing and waste recycling field.

2. Medium and Fine Crushing Equipment

There are cone crushers and impact crushers available for fine crushing. Sand making machines are often used in the final stage for sand making and shaping.

2. Medium and Fine Crushing Equipment

There are cone crushers and impact crushers available for fine crushing. Sand making machines are often used in the final stage for sand making and shaping.

Cone crusher is mainly aimed at crushing rocks with high hardness and abrasion, and its products have fewer powders.

Advantages: The use of laminated crushing makes good grain size, high crushing rate, and improves the quality of finished products.

The impact crusher is mainly suitable for crushing rocks with medium or low hardness and abrasion, and the products have more powdery materials.

If the demand for powder material is poor, standard cone crusher can be used for medium crushing and short-head cone crusher for fine crushing.

Vertical Shaft Impact crusher (sand making machine): Final product has excellent particle size, generally cubic shape, uniform fineness, coordinated gradation, and can meet the higher standard aggregate requirements;

3.Screening Equipment

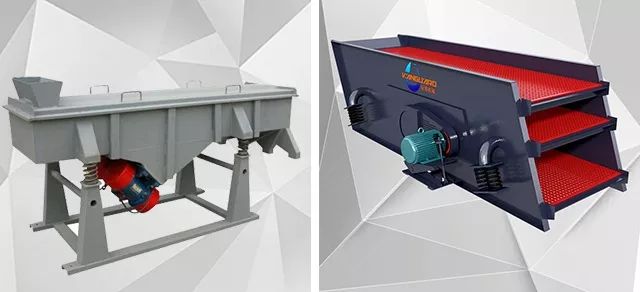

Stone screening equipment generally adopts linear or circular vibrating screen.

Vertical Shaft Impact crusher (sand making machine): Final product has excellent particle size, generally cubic shape, uniform fineness, coordinated gradation, and can meet the higher standard aggregate requirements;

3.Screening Equipment

Stone screening equipment generally adopts linear or circular vibrating screen.

Linear vibrating screen is suitable for small particle size screening and small production, and can be used for water-bearing material filtration.

The circular vibrating screen has high screening efficiency and large capacity, and is suitable for large-scale production.

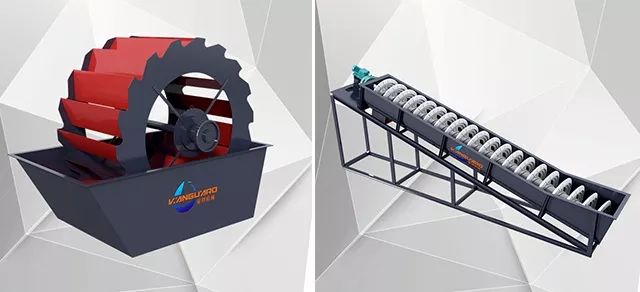

4.Washing Equipment

Machine-made sand products must be washed. The cleaning of sand and gravel products can remove impurities such as soil mixed with them, and control the content of fine powder. The washed sand and gravel as concrete aggregate can improve the quality of concrete and reduce the water consumption. The main washing equipment for crushed sand is wheel sand washer and screw sand washer.

For mud and stone powder in 0-4.75mm product, the machine-made sand can be obtained by washing with screw or wheel washing machine.

The circular vibrating screen has high screening efficiency and large capacity, and is suitable for large-scale production.

4.Washing Equipment

Machine-made sand products must be washed. The cleaning of sand and gravel products can remove impurities such as soil mixed with them, and control the content of fine powder. The washed sand and gravel as concrete aggregate can improve the quality of concrete and reduce the water consumption. The main washing equipment for crushed sand is wheel sand washer and screw sand washer.

For mud and stone powder in 0-4.75mm product, the machine-made sand can be obtained by washing with screw or wheel washing machine.

5.Matching conveying and dust removal system

Belt conveyor, which is essential for gravel and sand production line, is an ideal continuous conveying equipment with high efficiency, reliability and convenience.

The dust removal equipment avoids dust pollution in the production process. It is possible to choose the conveying equipment with good airtight performance and spray to ensure that the dust emission concentration is lower than the national standard.

Belt conveyor, which is essential for gravel and sand production line, is an ideal continuous conveying equipment with high efficiency, reliability and convenience.

The dust removal equipment avoids dust pollution in the production process. It is possible to choose the conveying equipment with good airtight performance and spray to ensure that the dust emission concentration is lower than the national standard.

Only by familiarizing with and understanding the above skills and principles, being practical and reasonable in planning and designing production line schemes, can we achieve the best results, customer satisfaction and win-win cooperation.