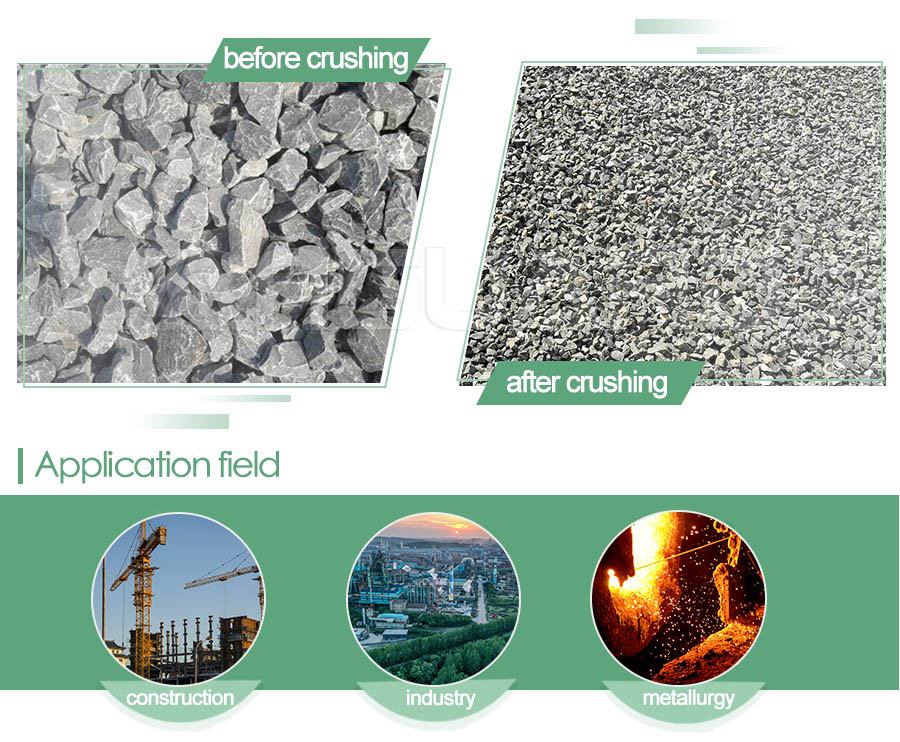

Limestone is a common raw material for machine-made sand and gravel. The hardness is generally 3 on Moh's hardness, which is medium hardness. It is widely used in construction, industry, metallurgy and other fields. The commonly used crushing equipment for limestone crushing production lines are hammer crusher, cone crusher, and impact crusher, etc. Usually in order to improve the output and quality of the limestone sand, the production line also needs to be equipped with conveying equipment, control systems, dust removal devices and other auxiliary equipment to ensure the continuous and efficient production of the limestone.

Here are a few of Vanguard customer's project situations for the limestone crushing production line, for your reference:

1.Mobile crusher:

(1). 100 T/H Mobile Crushing Plant in Shandong

Configuration:VPE Mobile Cushing Plant + VPF Mobile Cushing Plant

Material:Limestone

Capacity:100 T/H

(2).150 T/H Mobile Crushing Plant in Anhui

Configuration:VPM-3 Combined Mobile Impact Cushing Plant VPM-3 FX1315

Material:Limestone

Capacity:150 T/H

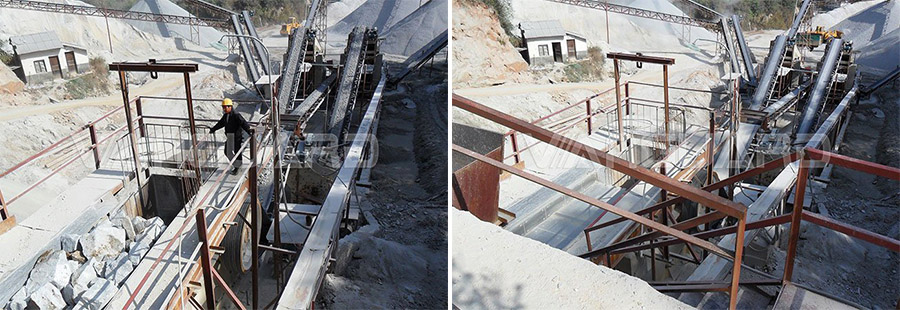

2.Stationary crusher:

(1). Sand and gravel production line in Russia

Configuration:6CX96 jaw crusher, 2YA1860 circular vibrating screen, PF1214 impact crusher, ZSW3896 vibrating feeder, belt conveyor.

Material:Limestone

Capacity:100-150 T/H

(2).200 T/H stone crushing production line in Guizhou

Configuration:ZSW4211 feeder, PE750*1060 jaw crusher, PF1315 impact crusher, 2 sets of 1860 vibrating screen

Material:Limestone

Capacity:200 T/H

In summary, the configuration of the limestone production line will be affected by the hardness of the material, brittleness, capacity and other factors and variables. According to the different material characteristics and production requirements, different production lines can be used. For example, for limestone with high hardness, poor brittleness and high capacity, the following production lines can be used: vibrating feeder, jaw crusher, impact crusher (heavy hammer crusher), circular vibrating screen; For limestone with moderate hardness, good brittleness and medium capacity, the following production lines can be used: vibrating feeder, jaw crusher, circular vibrating screen; For limestone with low hardness, strong brittleness, and small capacity, the following production lines can be used: vibrating feeder, hammer crusher, small-scale hammer crusher and vibrating screen. Of course, the production needs of different enterprises will also be different, and it needs to be adjusted according to the actual situation. At the same time, in the process of production line matching, it is also necessary to comprehensively consider factors such as cost, production efficiency and product quality to ensure that the expected production goals can be achieved in the end.

Vanguard Machinery is a professional manufacturer of mining machinery and equipment mainly engaged in the production of crushing and screening and supporting equipment, with more than 50,000 square meters of modern standard phone plant and the industry's top equipment processing and manufacturing capabilities, focus on details, adhere to quality, complete equipment models, perfect after-sales service.

- 上一篇: How to Choose a Site for a Sand and Gravel Plant? What Equipment is Needed to Build a Sand and Gravel Factory?

- 下一篇:Eight Departments, Including the Ministry of Industry and Information Technology, Issued a Document Clarifying the Top Ten Paths for High-quality Sand and Gravel Industry Development.