Sand and aggregate, as basic building materials, the market demand is still very large, which leads to sand aggregate being in short supply, prices have been rising, and more and more users are optimistic about the sand of stone projects, so how to choose the site of the sand and gravel factory? What equipment is required? These are top priorities, which are briefly described below.

I. Site selection conditions and requirements

Selection of the sand and gravel site is closely related to geographical, hydrological, geological, environmental protection and other factors, and the site selection shall meet the following conditions and requirements:

1. Location:The location should be convenient for transportation and logistics distribution, not far from major traffic arteries and urban centers, in order to facilitate the transportation of raw materials and the final products.

2. Terrain and landform: The site selection area should have flat or gentle slope terrain, which is convenient for facility construction and later maintenance.

3. Geological conditions:The site selection area should have a good geological environment to ensure the quality and production efficiency of sand and gravel materials. At the same time, the risk of natural disasters such as earthquakes and landslides should be avoided.

4. Hydrological conditions:The site area shall have sufficient water sources and drainage facilities to ensure production level and environmental protection effect.

5. Environmental protection requirements:Site selection should meet national and local environmental protection requirements, to ensure the sand of sand and gravel plant production and environmental benefits.

In terms of site selection suggestions, it is recommended to select experienced professional companies for evaluation and demonstration, fully consider production scale, market demand, competitive environment and other factors, and formulate a scientific and reasonable site selection plan.

II. Equipment selection and configuration

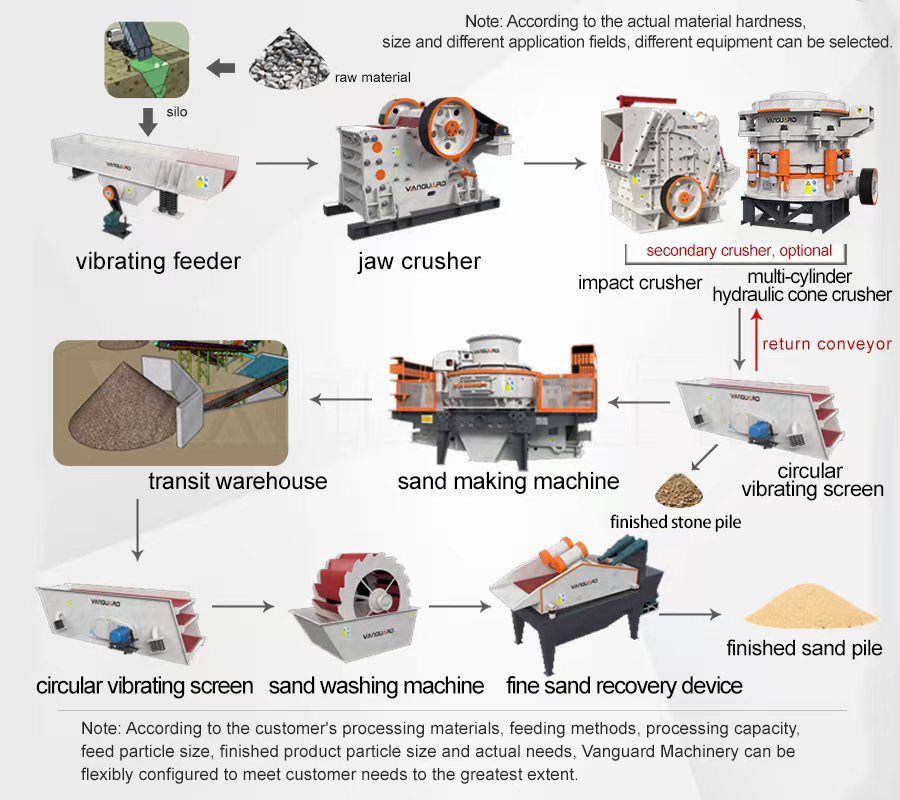

In general, the production process of sand and gravel plant is feeding, crushing, sand making screening and sand washing with the each process connected by a conveyor. The equipment mainly includes feeder, crusher (jaw crusher, impact crusher, cone crusher), sand making machine, vibrating screen, sand washing machine and a belt conveyor.

Due to the varying raw material size, hardness and particle size of the final product of different users, the equipment configuration will also differ. Below are a few examples of sand and gravel production lines for your reference.

1. 800 T/H sand and gravel production line in Sichuan Panzhihua

Configuration:Feeder, jaw crusher, cone crusher, vibrating screen

Material:Granite

Capacity:800 T/H

2. 300 T/H crushing and sand making production line in Fujian

Configuration:Feeder, jaw crusher, cone crusher, vibrating screen, sand washing machine

Material:Limestone

Capacity:300 T/H

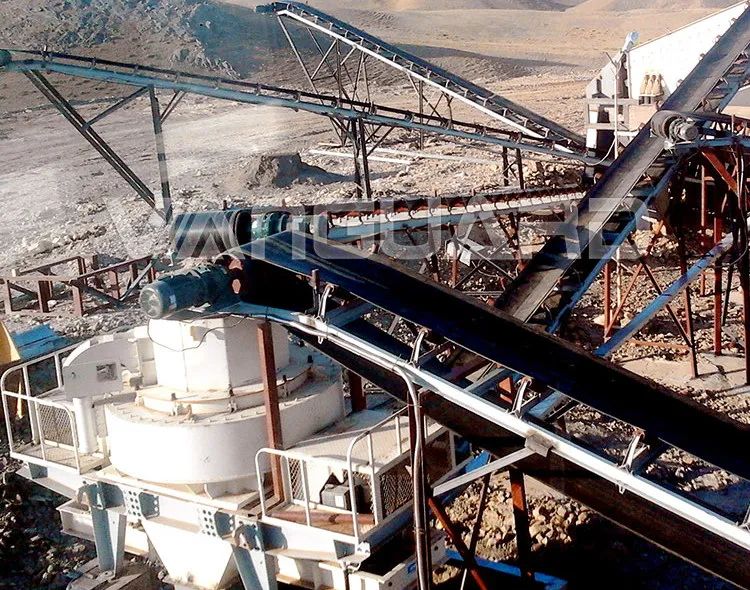

3. 200 T/H crushing and sand making production line in Qinghai

Configuration:Feeder, cone crusher, sand making machine, vibrating screen

Material:River stone

Capacity:200 T/H

In summary, the sand and gravel plant site selection is an important step in the sand and gravel plant construction, must consider a variety of conditions and requirements, develop a scientific and reasonable site selection plan, and choose efficient and excellent equipment, the sand and gravel plant equipment configuration should take into account production scale, raw material attributes and cost control factors, flexible selection of equipment configuration, in order to ensure the normal operation and production of the gravel plant.g>

Vanguard Machinery Tech is a mining machinery and equipment manufacturer integrating R&D, production, sales and service. Its products include crushing equipment, sand making and screening equipment, etc., which meet the needs of modern enterprises for environmental protection, high efficiency and safety. Complete models, perfect after-sales service, worthy of your trust.