The crushing production line is the mainstream configuration choice in the crushing and processing of sand and gravel materials. It can perform coarse crushing, medium crushing, fine crushing, ultra-fine crushing, sand making, screening and other operations to meet the needs of various industries, and it can also be applied to urban construction waste. In the project, a series of processes such as screening, recycling and reprocessing are carried out. From the perspective of mobility, crushing production lines can be divided into two types: stationary crushing lines, mobile crushing plant and semi-mobile crushing plant. The three types of crushing plant can be used for material processing in metallurgy, chemical industry, construction, hydropower, and other fields. Users can adopt various configuration methods according to the type, scale, and finished material requirements of material processing. So, how to choose these three crushing production lines? This article makes a comparative analysis of their respective characteristics.

1. Stationary crushing production line

The stationary crushing production line adopts the conventional process layout, reasonable equipment configuration at all levels, complete and mature construction and operation, strong compression resistance, wear resistance, long service life, convenient maintenance, and the finished aggregate has good shape and high quality. However, the stationary crushing plant needs to be built as a foundation and a large investment in civil engineering and labor. If it needs to be transferred, the foundation needs to be dismantled and rebuilt. The requirements for site selection are relatively high, and the site needs to be fully utilized for planning and layout. It is suitable for large-scale and long-term mines with stationary production sites.

Product advantages:

1. It is convenient for comprehensive management with production and living facilities systems and comprehensive treatment conditions for environmental protection, which can effectively control production costs.

2. One-time installation and debugging can be produced continuously, which saves the adjustment time spent on moving the site.

3. The spare parts and spare parts warehouse are sufficient to meet the needs of continuous production.

Customer Site

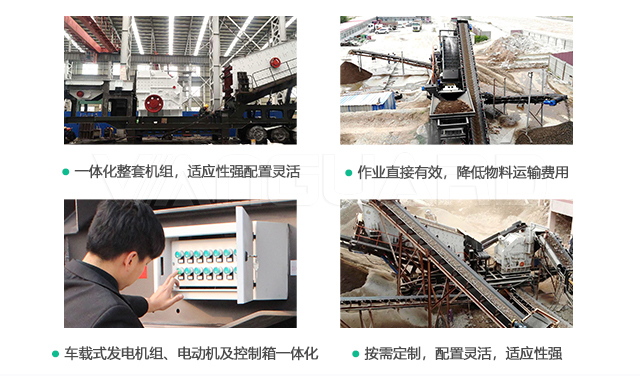

2. Mobile crushing production line

The mobile crushing station eliminates the obstacles brought by the crushing site, environment, complicated basic configuration and complicated logistics to the crushing operation. It can go directly to the site and start the operation in a short time, avoiding material transfer, reducing transportation costs, convenient and flexible, without the need to build a workshop and Civil foundation, suitable for small and medium-sized mines that frequently transfer. The mobile crushing plant is a production line that integrates the processes of receiving, crushing, and conveying. According to different requirements, it can be composed of first crushing and then screening, first screening and then crushing or seconderay crushing for coarse and fine crushing, and tertiary crushing and screening system for coarse, medium and fine crushing.

Vanguard Machinery series mobile crushing plant is divided into tire type mobile crushing plant and crawler type mobile crushing plant.

(1)Tire type mobile crushing plant

The tire-type mobile crushing plant needs to rely on the semi-trailer head for traction. The project cycle is short and the follow-up is fast, which not only reduces the investment risk and opportunity cost of investors, but also avoids the reconstruction work after the project is completed, which is more economical and eco-friendly. It is suitable for crushing sand and gravel materials such as construction waste treatment, earthwork and road construction.

Product advantages:

Customer Site

(2)Crawler type mobile crushing plant

The chassis of the crawler-type mobile crushing plant adopts a crawler-type full rigid structure, which has high strength and good passability, can achieve climbing operations, and can be hydraulically driven by itself. It is mostly used in mining, open-pit coal mines and other harsh operating environments. The crawler-type mobile plant uses the crawler to walk, which can realize in-situ steering, drive it to the trailer through wireless remote control, and send it to the work site, with a high degree of automation.

Product advantages:

1. Improve the utilization rate of equipment, have good mobility, and extend with the site.

2. Save production costs: reduce the high cost of material transportation.

3. Easy to install: save the basic cost of installation and manpower for installation and adjustment.

4. Convenient maintenance: it can be directly shipped to the repair shop for maintenance.

5. Simplify the production process: move forward with the mining surface, simplifying the transportation link.

Customer Site

(3) Semi-mobile crushing production line

Semi-mobile crushing is a multi-integrated frame structure solution consisting of one or some crushing and screening unit modules. This series of mobile plant is especially suitable for multi-site quarries where equipment needs to be moved between different locations on a regular basis. The semi-mobile crushing plant includes crushing, screening or feeding equipment, non-standard parts such as steel structure brackets, hoppers, buffer silos, etc., and standardized design and production parts such as steel grating platforms, italics, and handrails. The semi-mobile crushing plant itself does not have the walking function, there is no concrete foundation connection on the ground with the short construction period and the less civil work.

Product advantages:

1. The structure design is compact, space-saving, free of basic installation, and can be quickly relocated and reassembled according to construction needs;

2.The assembled type adopts advanced modularized, non-welded frame structure design, with high strength and reliability. At the same time, the whole-machine assembled design is more convenient for transportation and installation. It is especially suitable for installation in narrow and difficult places to transport such as underground mines and high-altitude mines.

3. The finished product has an excellent particle shape, and the finished product is cubic after crushing, with a high content of fine particles, which can meet the needs of some high-quality aggregates.

4. The thin oil lubrication system adopts the redundant design of double oil pumps and double filters, which is easy to control with strong adaptability to prolong the service life of parts.

The above three crushing production lines can flexibly choose different configuration schemes according to the user's own needs and the actual situation of the site in the actual stone crushing production and processing. Vanguard Machinery is a professional manufacturer of stone crushing equipment, which can provide you with various types of crushing, sand making, sand washing, screening and other equipment, and is at the forefront of the industry in meeting customers' customized needs to maximize the interests of customers with professionalism and innovation. Welcome new and old customers to visit.