Aggregate is a general term for materials such as sand, egg (gravel) stone, crushed stone, boulder, and stone, which is the main building material for structures such as concrete and masonry in hydraulic engineering. It is divided into coarse aggregate and fine aggregate. Coarse aggregate refers to aggregate with particle size greater than 5mm, and fine aggregate refers to aggregate with particle size less than 5mm. The capacity of the aggregate production line is different with the different equipment. The reasonable configuration of the aggregate production line can not only effectively increase the capacity, but also reduce the investment cost. This article briefly introduces the equipment required for the sand and gravel aggregate production line and several configuration schemes for sand and gravel production for your reference.

A complete aggregate production line is mainly composed of a feeding system, crushing system, sand making system, and screening system. It will produce high-quality aggregate only by cooperating.

1.Feeding system

The equipment usually used in the feeding system is a vibrating feeder, whose function is to send the material from the silo to the receiving device evenly, regularly and continuously.

2. Crushing system

The crushing system has a variety of equipment to choose from, such as a jaw crusher, impact crusher, hammer crusher, cone crusher, etc. Its function is to crush and produce stones of different specifications according to user needs. The main material is limestone, granite, marble, basalt, iron ore, river pebbles, shale, bluestone, coal, cobblestone, etc.

The type and production capacity of crushing equipment is mainly determined by the type and nature of materials, output, graduation requirements, and site.

3.Sand making system

The equipment used in the sand making system is a sand making machine. The sand making machine optimizes the structure of the crushing cavity. The two modes of crushing between stones and crushing between stone and plate can be quickly transformed. Well, compared with the sand before sand making, the economic value is increased by more than 30%. Therefore, some sand and gravel factories usually add a sand making machine after the crushing equipment to obtain the high-quality stone.

4. Screening system

The screening system is to screen different specifications of sand and gravel through the vibrating screen. The vibrating screen can be equipped with 2-4 layers of screen mesh, which has high screening efficiency and productivity. It is widely used in mining, coal, smelting, building materials, fire-resistant materials, light industry, chemical industry, medicine, food, and other industries.

Aggregate production line solution:

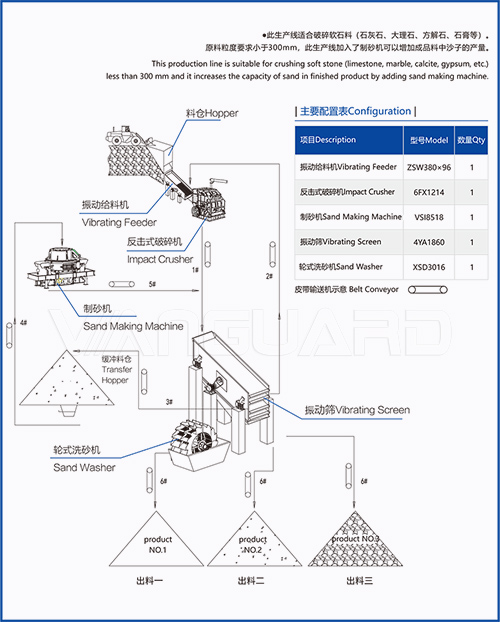

1. Solution of 80-120 T/H crushing and sand making production line

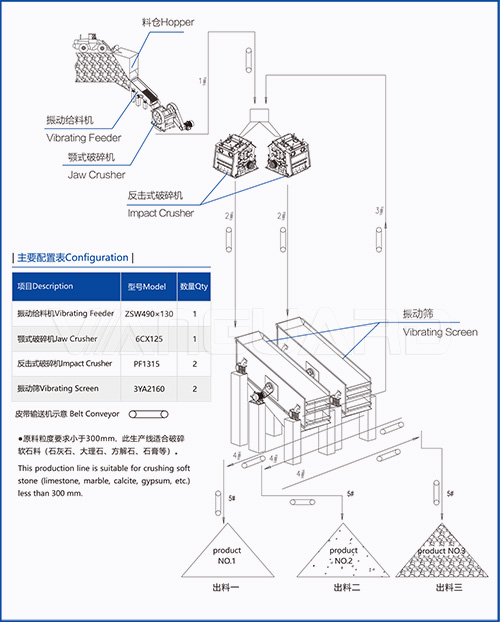

2. Solution of 250-350 T/H crushing production line

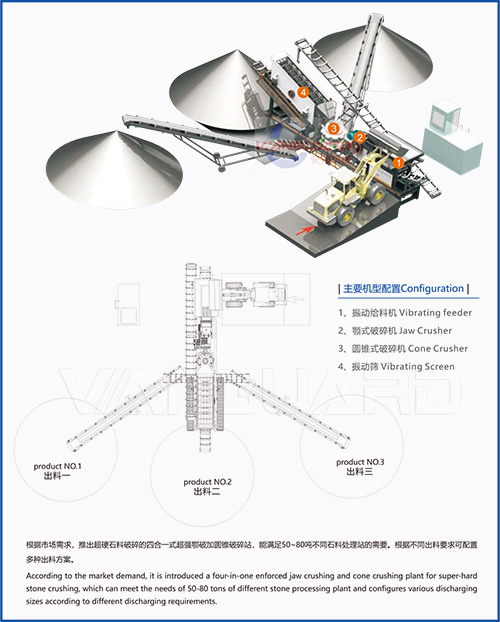

3. Solution of 50-100T/H mobile crushing production line

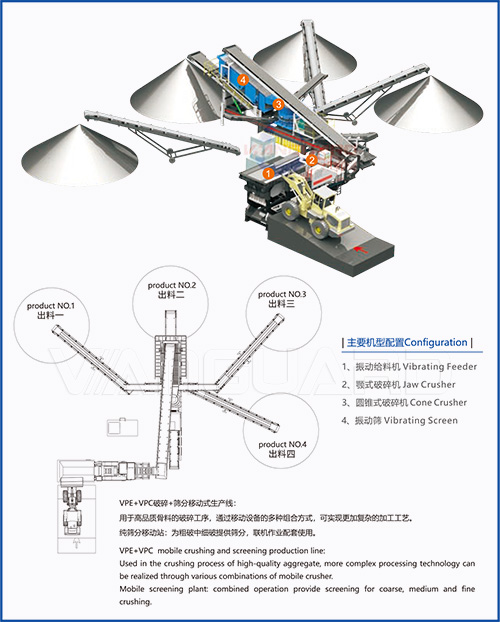

4. Solution of 100-200 T/H mobile crushing production line

The above solutions for the aggregate production line are for reference only. You can contact us if you want to know more relevant knowledge and configuration schemes.