The sand and gravel production line is to process various rocks, sand and gravel and other large stones through orderly coarse crushing, medium crushing, screening, sand making, sand washing and other processes, and finally make high-quality sand and gravel aggregate required in infrastructure construction. The uniform sand density and the reasonable gradation, which is more in line with the requirements of construction sand and can improve the construction quality. This article mainly introduces how to configure the sand and gravel production line and its process.

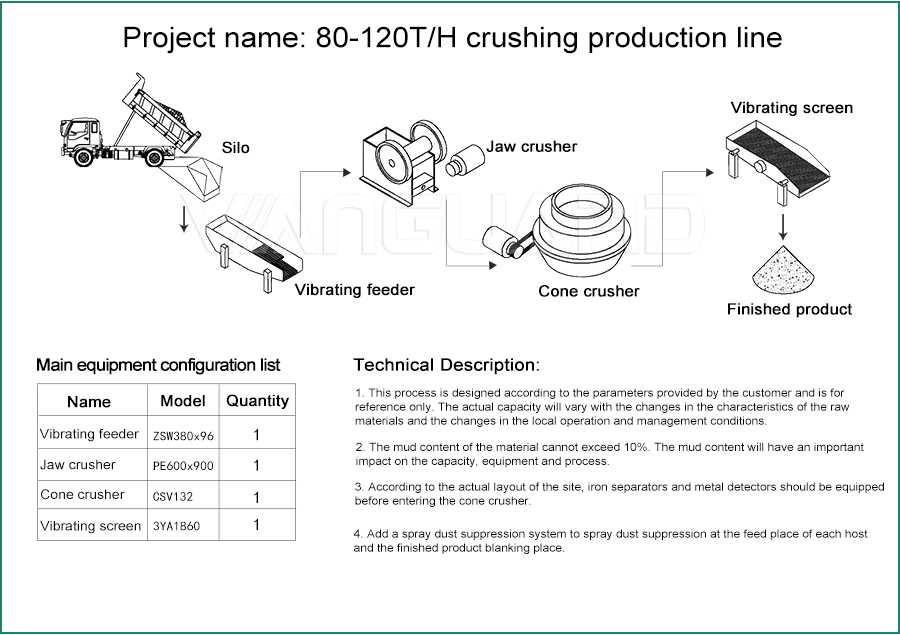

1.Shanxi Project

Material:river stone

Capacity:100 t/h

Production line configuration:feeder, jaw crusher, cone crusher, vibrating screen

The customer's production line is located on the edge of the river beach, and the sand making raw materials are mainly river stone and pebbles on the river beach. The main component of riverstone is silicon dioxide, followed by a small amount of iron oxide and trace elements and compounds such as manganese, copper, aluminum, and magnesium. There is no accurate fixed value for the hardness of river stone, because they are not pure substance, and the Mohs hardness of silica is 7, so it can be generally considered that the hardness of it is around 7.

Because the customer's materials have high hardness and different sizes, it is necessary to choose a crusher with a high hardness of the crushed material. Therefore, Vanguard Machinery's technical engineers finally determined the plan after detailed technical discussions, and chose the feeder and the jaw crusher, cone crusher, and vibrating screen as the configuration plan. This scheme is suitable for crushing materials with high hardness, abrasiveness index, high capacity and good grain shape.

Main workflow

First use a jaw crusher to coarsely crush the material, and then use the function of the cone crusher to adjust the size of the discharge opening according to the abrasive condition to perform medium and fine crushing of the coarsely crushed material, and then further screen through the vibrating screen to obtain the finished material.

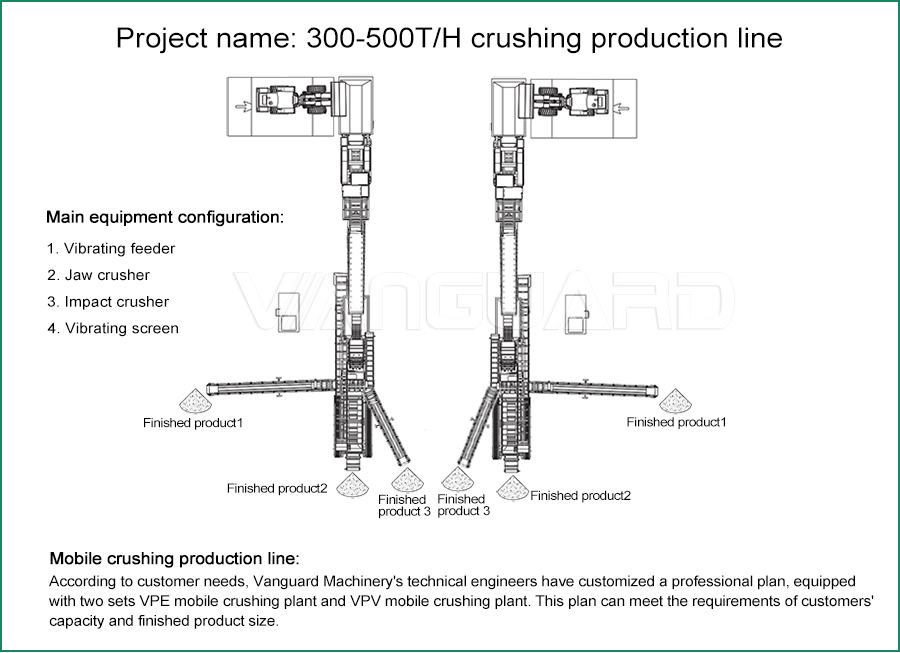

2.Guangdong Project

Material:Limestone

Capacity: 500 t/h

Configuration: VPE mobile crushing plant×2+VPV mobile crushing plant×2

The locally mined limestone contains between 15-30% soil and needs to be separated first. Limestone has a Mohs hardness of 3, which is a soft material. Combining the properties of limestone and customer capacity requirements, Vanguard Machinery has designed a tailor-made plan for customers, equipped with two (sets) of mobile jaw crushing plants and two (sets) mobile impact crushing plants with a reasonable design, the adjustable finished product size, and the sand and gravel specifications meet the construction requirements.

Main workflow

Limestone is directly sent to the main processing equipment jaw crusher by the vibrating feeder on the mobile jaw crusher plant for processing. After the initial treatment by the mobile jaw crusher, the particle size of the limestone becomes smaller, and it is sent to the mobile impact crusher by the belt conveyor to be crushed again.

The above sand and gravel production line configuration is for your reference only. The actual landing of the entire project involves many links, so customers need to consult professional technical engineers according to their conditions to ensure the smooth start of the project and profitability.