The Republic of Guinea is located on the west coast of West Africa. The country is rich in resources, and its bauxite ranks first in the world. The coastal areas have a tropical monsoon climate, with high temperatures and rain all year round with abundant rainfall.

The main processing raw material of Vanguard Machinery's 1000 t/h bauxite crushing project is bauxite, also known as aluminum, aluminous soil. It is an earthy mineral composed of alumina with low hardness, insoluble in water and soluble in sulfuric acid, which can be used for aluminum smelting and the manufacture of refractory materials. In order to improve the comprehensive recycling rate of bauxite, it is necessary to crush the bauxite.

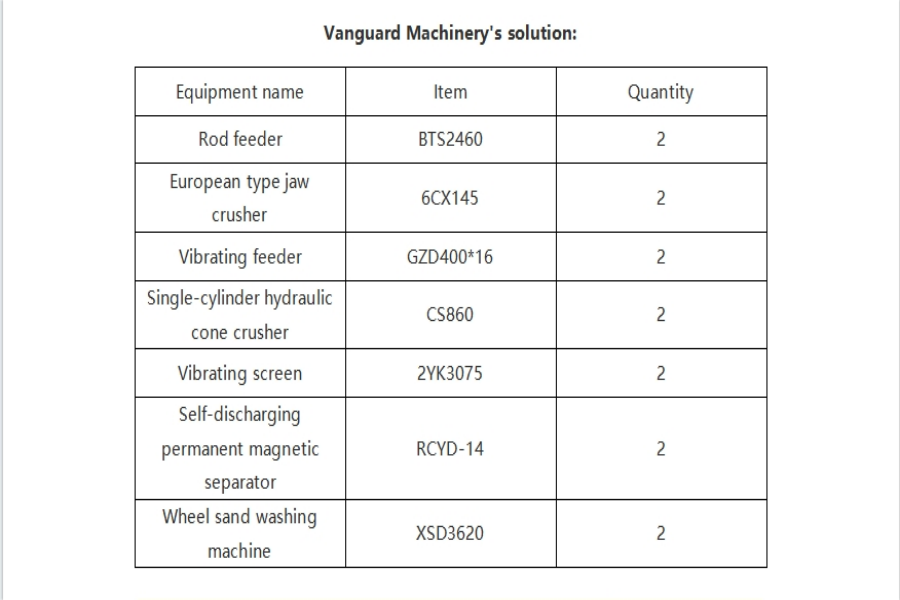

Technical requirements for Vanguard Machinery's 1000 t/h bauxite project:

Raw material: bauxite

Capacity: 1000 t/h

Final product material requirements: 0-100 mm

The proportion of raw materials: 0-40 mm materials account for 40%, and materials below 100 mm account for 50%.

Things that need attention in the project: The area is rainy, which will cause the viscosity of the raw materials to increase, so material blockage must be avoided. The demand for production output is large, and the stable operation of the equipment is required.

The raw materials of this project are highly viscous and the site conditions are special. Vanguard Machinery's technical engineers analyzed, discussed and designed it based on the local environmental topography and the specific conditions of the customer. After fully understanding the customer's production line capacity, final particle size, and investment cost budget. After meeting the customer's needs, we will tailor the production line and layout plan for the customer, and focus on improving and optimizing the following aspects to ensure that the design plan can achieve the desired effect.

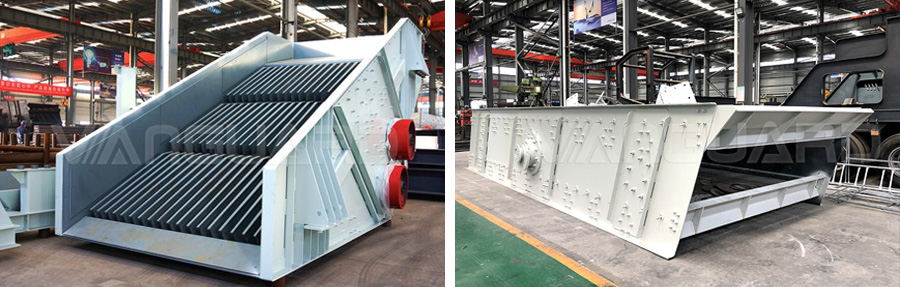

1. Considering the high viscosity of the customer's raw materials, we selected a rod feeder for the main equipment of the feeding part, and improved the inlet and outlet of the hopper so that the feeding part can be smooth without clogging, and the finished material classification can be adjusted vibrating screen configuration is used to achieve multi-stage screening, which can synchronize multi-stage discharging and accurately control the particle size of final product;

2. Select Vanguard Machinery's star product 6CX series European type jaw crusher for primary crushing. It is specially designed with a detachable structural rack, optimized cavity structure, double wedge block adjustment device, elastic limit shock absorption device, and integrated motor base with high crushing efficiency, low investment cost, long service life and stability. It can process ores with compressive strength not higher than 320 MPa to medium particle size at one time.

3. The standard two-stage crushing process, multiple crushers and multiple screens, and the cooperation of multiple units can achieve a production line with a daily output of ten thousand tons. Combined with the transfer hopper, it can be configured into a large or super-large crushing production line. The secondary crushing equipment uses a single-cylinder cone crusher and laminated crushing, high production efficiency, wear-resistant and durable, low operating cost, easy to control.

4. The entire line adopts a steel frame assembled structure, and each part is connected with welds, screws or rivets with a short construction period, quick production, and portable disassembly and assembly.

Commissioning and delivery:

Installation and debugging personnel from the front line of project production participate in and manage the project equipment installation and debugging throughout the entire process, quickly solve common problems that arise during on-site steel frame assembly and installation work, and adjust the construction plan in real-time. Vanguard Machinery completed the installation and commissioning work of the Guinea project with high quality within a limited time.

The 1000 t/h bauxite crushing production line project in Guinea was successfully put into production within a short period of time. This not only fully reflects the outstanding crushing technology strength and product advantages of Vanguard Machinery, but also won further recognition for Vanguard Machinery in the region. Once again proved that our service commitment is not a slogan, a concept and an advertisement, but our service commitment is seriously practiced.