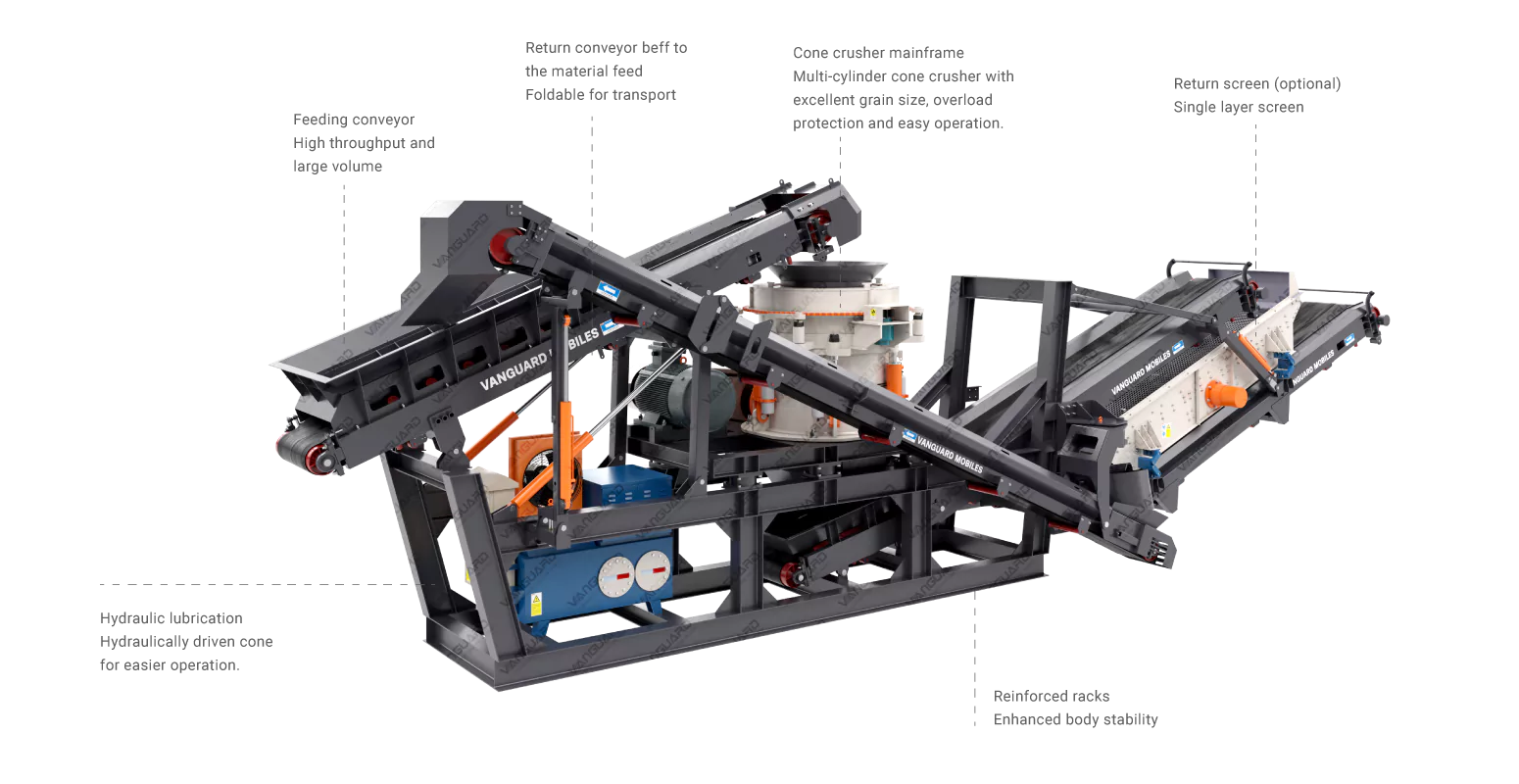

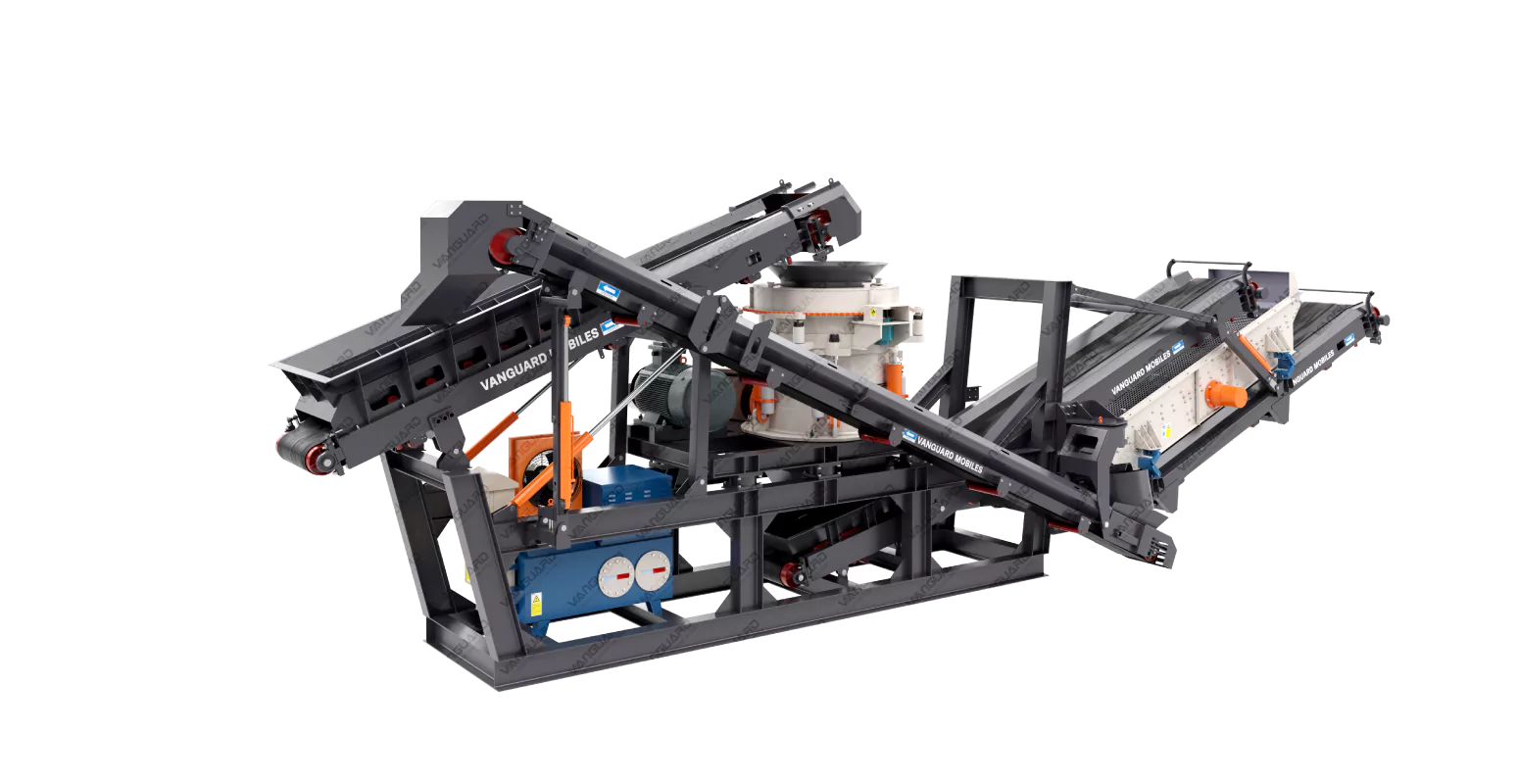

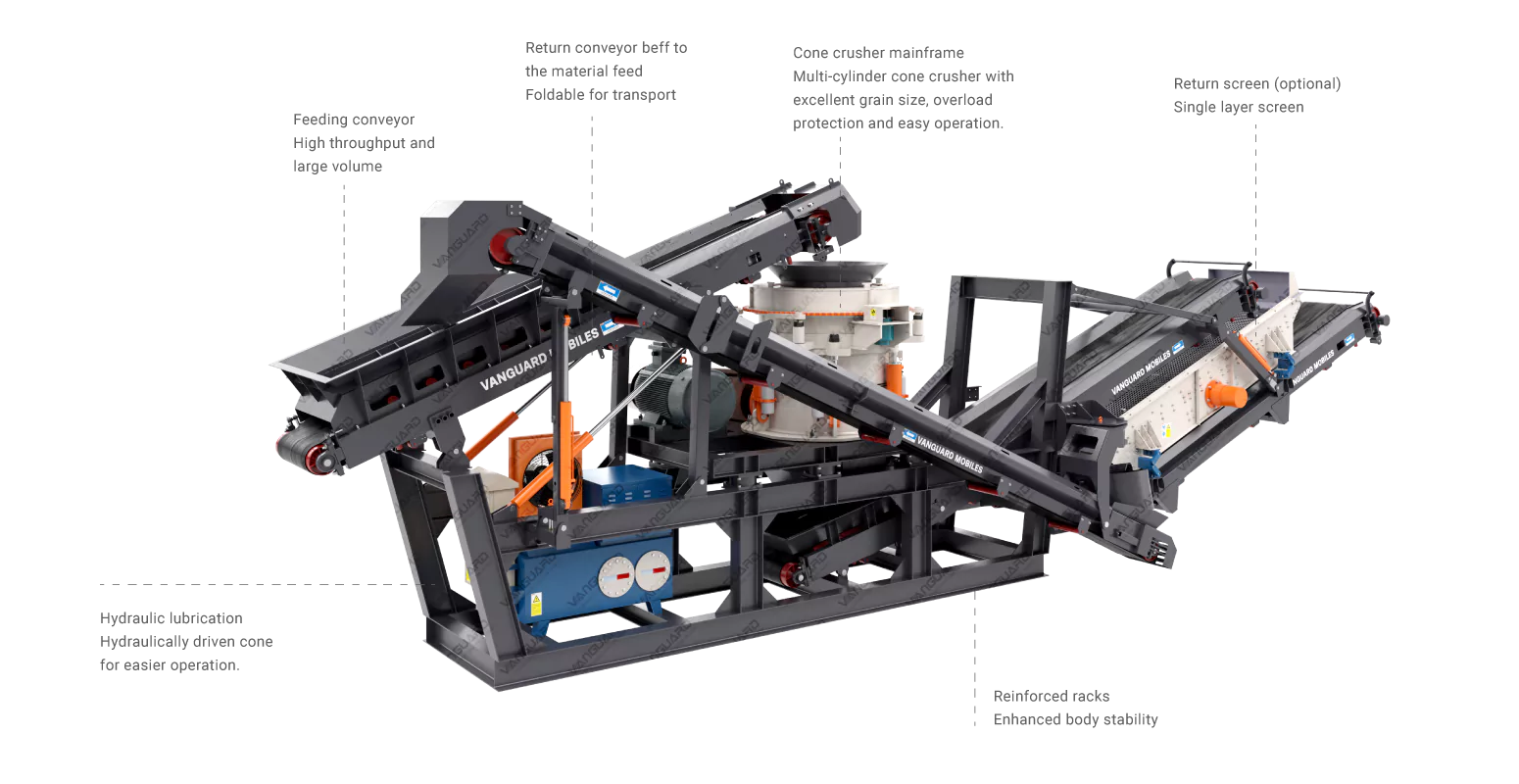

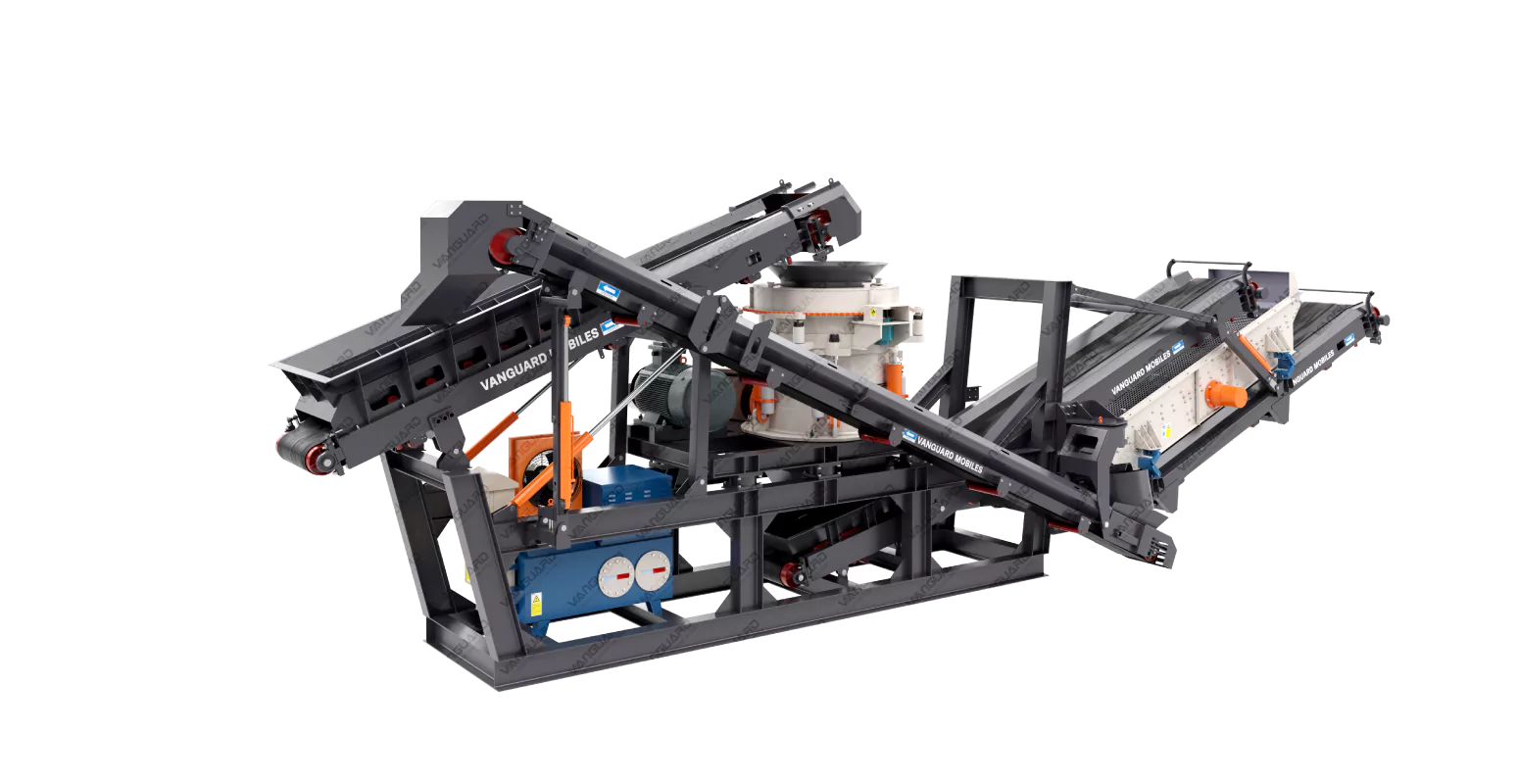

MBPSeries Mobile Cone Crushing Plant

MBPSeries Mobile Cone Crushing Plant

The material is crushed by the principle of lamination crushing, with high crushing efficiency and low wear of wearing parts. After crushing, the finished product is cubic with high fine-grained content, which can well meet the needs of some high-quality aggregates at this stage.

This series of cone crushers has a larger feeding port, which can exert maximum performance to adapt to various crushing processes. It is widely used in medium crushing, ultra-fine crushing, stationary and mobile crushing plants. The optimized design of crushing speed, eccentricity (stroke) and cavity design are perfectly combined to provide higher capacity and better product quality.

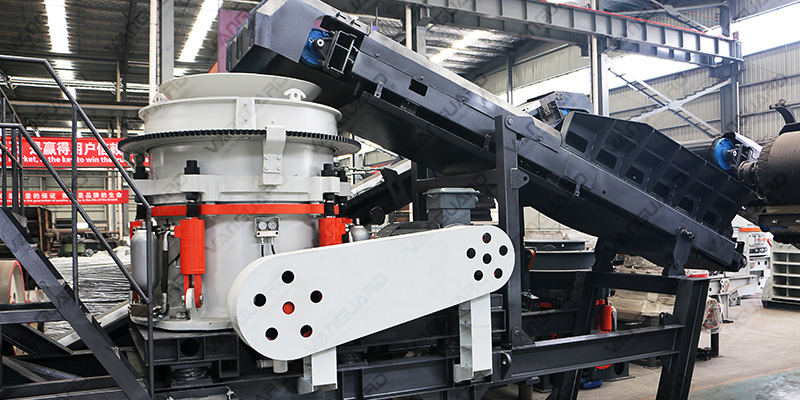

The thin oil lubrication system adopts the redundant design of double oil pumps and double filters, which can be lubricated before the equipment is started, with strong adaptability, easy control, and prolongs the service life of parts.

The integrated installation method of the motor base and the crusher frame not only saves the installation space of the jaw crusher. Moreover, due to the synchronous movement of the frame, the motor base and the motor, and the adjustable motor base, the tension of the V-belt can be adjusted so that the service life of the V-belt is longer.

Capacity:150 t/h

Max. Input size: ≤500mm

Output size: ≤25mm

Processing materials: granite

Project advantages: The mobile crushing plant production line has a short construction period, does not need to build a concrete foundation for the equipment, and builds a sand and gravel production line quickly, efficiently and economically, which not only reduces the investment risk and opportunity cost of investors, but also more economical and eco-friendly.

| Project | Device Name | Models and Specifications | Power (kW) | Amount | |

|

HP300 cone crusher + 1542 return screen |

cone crusher | equipment | HP300 | / | 1 |

| triangle belt | Standard | / | 7 | ||

| motor | Standard | 250 | 1 | ||

| return screen | equipment | 1542 | / | 1 | |

| vibration motor | Standard | 3.7 | 2 | ||

| modular steel structure | Standard | / | 1 | ||

| feeding conveyor | Specification | B1000*6m | 7.5 | 1 | |

| drive mode | electric drum drive | / | 1 | ||

| main conveyor | Specification | B1000 * 8.7m | 7.5 | 1 | |

| drive mode | electric drum drive | / | 1 | ||

| underscreen conveyor | Specification | B1200*6.2m | 7.5 | 1 | |

| drive mode | electric drum drive | / | 1 | ||

| transfer conveyor | Specification | B650*2m | 3 | 1 | |

| drive mode | electric drum drive | / | 1 | ||

| return conveyor | Specification | B500*9.5m | 5.5 | 1 | |

| drive mode | electric drum drive | / | 1 | ||

| Electrical System | Electric control cabinet | Host soft start, electrical components Chint | / | 1 set | |

| Belt conveyor folding cylinder | / | 1 set | |||

| Hydraulic Pumps, Valves, Stations and Tubing Accessories | / | 1 set | |||

| Total power 288.4KW | |||||

Thank you for your interest in Vanguard Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!