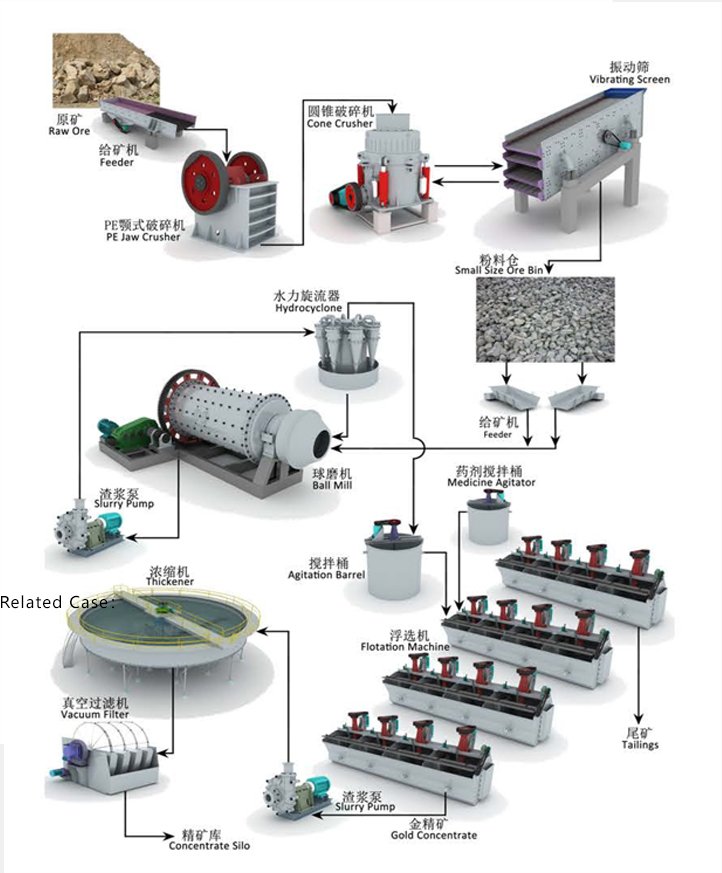

Introduction:Flotation is a common beneficiation method used by gold concentrators to process rock gold ore. It is often used to process gold-bearing sulfide minerals with high floatability. The flotation process can enrich the gold in the sulfide minerals to a greater extent and the tailings can be directly discarded and the beneficiation cost is low. 80% of the rock gold mines in my country are selected by this process.

Capacity:12-1000t/h

Application:Gold flotation process suitable for treating fine particles of gold can be high floating quartz veins sulfide ores containing gold and polyme