The multi-cylinder cone crusher has the characteristics of large production capacity, high efficiency, laminated crushing, excellent final product particle shape, simple operation, and high degree of automation. It is widely used in medium and fine crushing in the sand and gravel aggregate industry and mining industry, especially in medium-hard material processing systems. In the production of multi-cylinder hydraulic cone crushers, some on-site application methods can be used to effectively improve the crushing effect of the cone crusher.

Power Control

In the process of applying multi-cylinder hydraulic cone crusher for on-site work, its main work control method is the change of feeding amount. Therefore, in the specific working process, if the feed volume is large, the driving power requirements of the mechanical equipment will also be large. To ensure its working quality, its working power should be controlled between 75% and 90%, and its maximum power should not exceed the rated power. At the same time, during on-site work, operators should strictly avoid running the crusher in a low-power state. If it is running, its running time should not exceed 5 seconds. In specific on-site crushing operations, the power of the crusher must reach more than 40% of the rated value.

Material level control

In field applications, if the multi-cylinder hydraulic cone crusher has been running for more than 30 minutes but still cannot feed, the crusher needs to be temporarily shut down and then turned on again when feeding is possible. When the cavity of the multi-cylinder hydraulic cone crusher is crowded with materials, its optimal working condition is when the operating power reaches 75% to 90% of the rated value. In specific operations, the work of the multi-cylinder hydraulic cone crusher needs to be controlled by changes in the feed volume, and the discharge port is used as an auxiliary control facility. The adjustment of the discharge port can effectively compensate for the wear of the liner. Ensure the stability of product particle size. At the same time, the tight edge discharge port adjustment and cavity type selection can also be used to ensure that the crusher cavity is filled with materials. Under normal circumstances, the height of the materials in the cavity should exceed the material distribution plate by more than 300mm. And the driving power should be kept stable and controlled at 75% to 90% of the rated value.

During on-site operations, the radar level meter can be used to detect the material level in the crusher cavity, or it can be used as a device to control the signal input of the material quantity control loop in the crusher. When the material in the crusher cavity is crowded Finally, the driving power can be further optimized through reasonable adjustment of the discharge port. For example, after the crusher discharge opening is increased, the given material level driving power of the crusher will be reduced, meanwhile, the feeding amount in the crusher cavity will be increased; After the reducing crusher discharge opening, the given material level driving power of the crusher will be increased, meanwhile, the feeding amount in the crusher cavity will be reduced.

Multi-cylinder hydraulic cone crushers have exerted good application value in many fields today. Compared with traditional crushers, the installation of multi-cylinder hydraulic cone crushers is simpler and more convenient, and their work efficiency and work quality are also higher. In production, it is necessary to control the on-site application of multi-cylinder hydraulic cone crushers and perform targeted operations to improve the production efficiency and quality of the equipment.

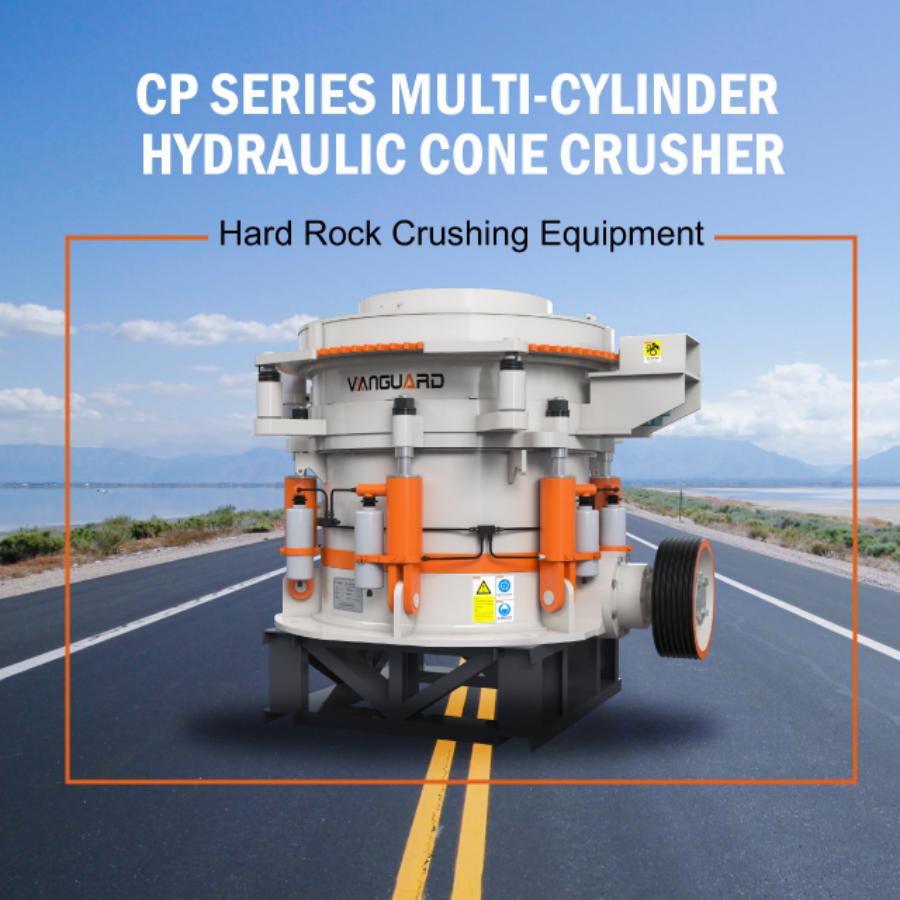

As one of the flagship products of Vanguard Machinery, the CP series multi-cylinder hydraulic cone crusher has been widely used in production lines everywhere and has achieved good market response. This series of crushers has a good grain shape with laminated crushing, accurate and reliable full hydraulic control, and easy equipment maintenance. They are your right assistant on the road to producing high-quality aggregates.