Cone crusher has a very important position in crushing equipment for its diverse types and quite wide application. Single-cylinder cone crusher, multi-cylinder cone crusher and spring cone crusher are common in the industry. Compared with the spring cone crusher, the single-cylinder cone crusher is easy to operate. Compared with the multi-cylinder cone crusher, there is a low comprehensive application cost of the single-cylinder cone crusher. Therefore, single-cylinder cone crushers are very popular in the market.

Working principle:

When the single-cylinder cone crusher is working, the motor drives the small gear of the crusher, meanwhile, the small gear drives the big gear, and the big gear assembly drives the eccentric sleeve assembly and the main shaft assembly. Centered on the theoretical vertical line, it revolves in the copper bushing, and the main shaft assembly is eccentric. The centerline of the main shaft can realize rotation in the copper sleeve. When the material is added to the crushing cavity, the main shaft assembly rotates slowly in the eccentric copper sleeve under the resistance of the material. The running trajectory of the inner cone seems to swing back and forth in the crushing cavity while rotating slowly. The material is squeezed and broken by the swinging inner cone, and the broken material is discharged from the discharge port.

The main technical parameters:

Capacity: 15-2200t/h

Feed size: 0-370mm

Power: 90-750kw

Advantages and characteristics:

1.Good grain shape

The material is crushed by the principle of lamination crushing, with high crushing efficiency and low wear of wearing parts. After crushing, the finished product is cubic with high fine-grained content, which can well meet the needs of some high-quality aggregates at this stage.

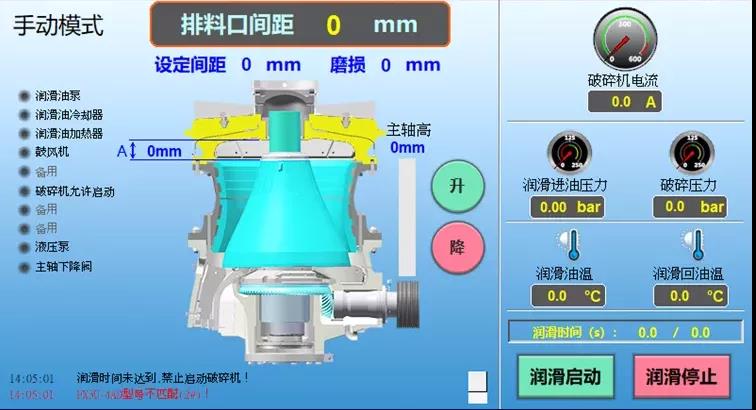

2.High degree of automation

After continuous improvement and upgrading, the single-cylinder cone crusher adopts a PLC and touch screen fully automatic control system to fully ensure the safe operation of the equipment.

3.Large production capacity and low energy consumption

The machine is designed with the right combination of crushing stroke, crushing speed and crushing cavity shape, which is 35%~60% higher than the output of the old-fashioned cone crusher.