- Home

- Video

- Products

- Stationary Crushers

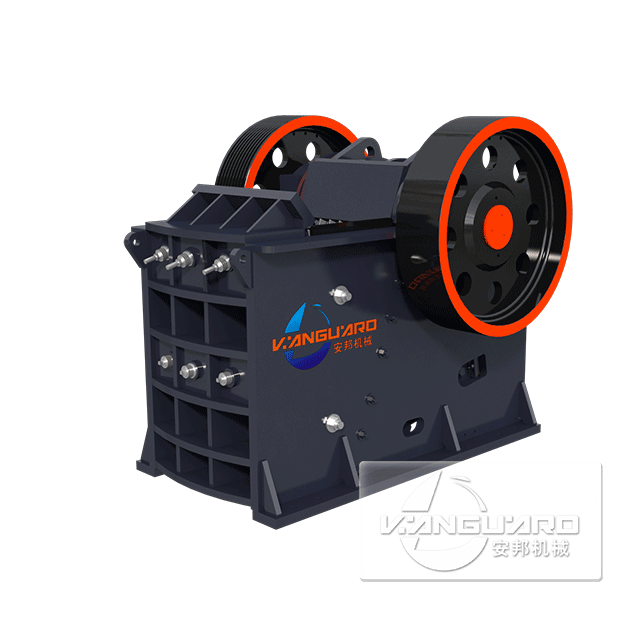

- PE/PEX Jaw Crusher

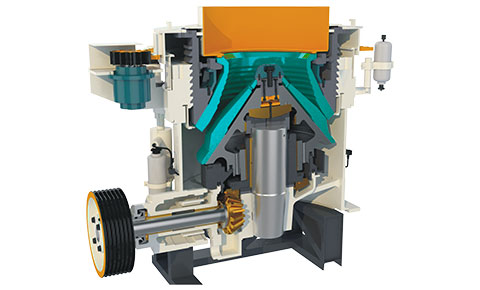

- Spring Cone Crusher

- PEW Series Hydraulic Jaw Crusher

- 6CX Series European Type Jaw Crusher

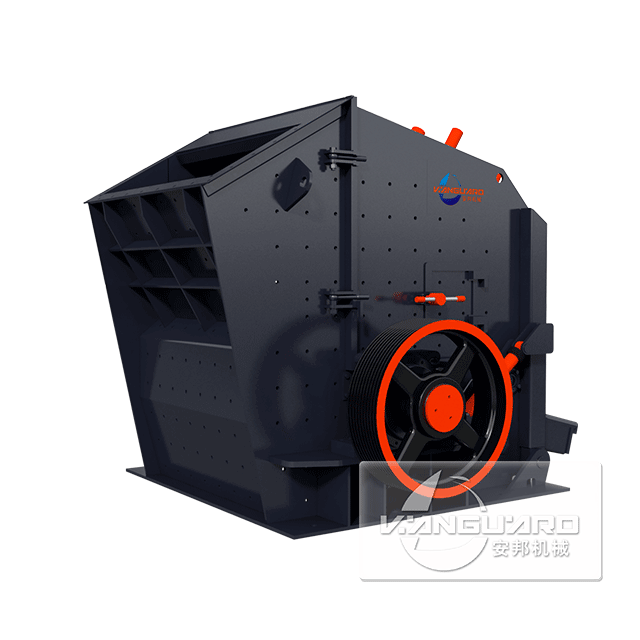

- PF/PFV Series Impact Crusher

- 6FX Series Hydraulic Impact Crusher

- CSV Series Symons Cone Crusher

- CS/CH Series Single-Cylinder Cone Crusher

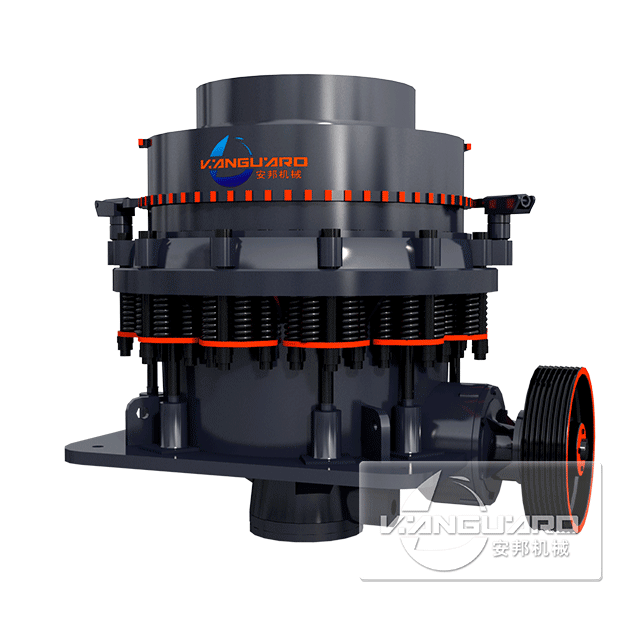

- CP Series Multi-Cylinder Hydraulic Cone Crusher

- ZSW Series Vibrating Feeder

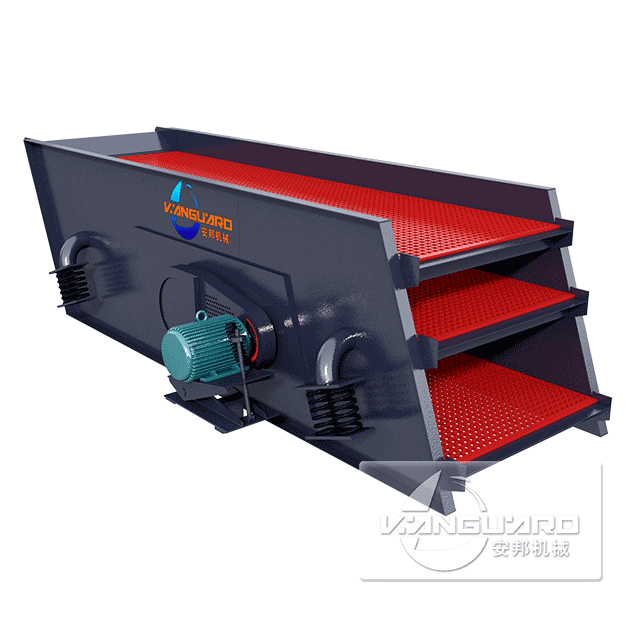

- YA Series Vibrating Screen

- ZY Series Self-aligning Damping Vibrating Screen

- Belt Conveyor

- More>>

- Solution

- News

- Case

- Service

- About